-

Posts

97 -

Joined

-

Last visited

Other groups

Profile Information

-

Gender

Male

-

Location

Edmonton, Alberta Canada

-

Interests

Muscle cars, sports, travel

-

Legal Name

Kevin Dyck

-

Occupation

Refrigeration Technician

-

My Monte ('s)

1970 350 - Auto

Other: LS engine

5-speed etc.

Profile Fields

- Member

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

colonel's Achievements

-

Hey, how about that. Good to see. Looks good on your fridge. Obviously mine was not the first Monte in the collector series. Anybody know if John is a club member? I like your online name. I used to be a member at a private golf club named Blackhawk. Very nice place to play if your reasonably good at it. What inspired you to use Blackhawk?

-

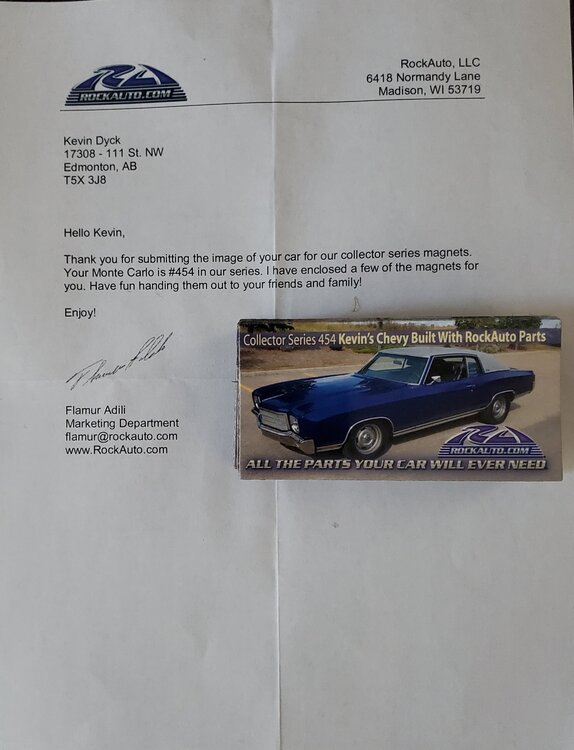

Thanks guys. Last October I decided to check how Rockauto got the cars they put on the magnets and it was as easy as sending in some appropriate pics so I did. Got an email from them mid August saying my Monte had been selected, which I was rather happy to hear, and a few weeks later they arrived. I would have thought there were some other members that had been selected by now. You do have to send in the pics as they don't send people out to car shows to find the cars and I'm pretty sure they want to see you have purchased at least some parts from them for your Monte. There are certainly many cars in this group that are worthy of being on one of their magnets.

-

colonel started following Soon… and RockAuto Magnet

-

- 12 replies

-

- 10

-

-

Just to put it out there, ya know, to help with your decision and all. Sandy and April get along pretty well, with our without wine in their hands, so you know she would have a good life out here if you choose the car. 😉 Really amazing find. The car that is. Well april too!!! Ahh geez I better stop before I get into more trouble with Sandy!!!! Hoping to see the car in May.🤞 Well April too!! There I go again.

-

Definately a keeper. Good work with the video too. Steady hand and framed well. Why make the car go away if you would like the option of buying it back at a higher price?? Oh well. In the hands of a person that will do a good job of cleaning it up, sorting out problems and getting it to the next worthy owner.

-

Looks pretty good Aaron, although it does appear to be missing the lighter😉😒🙄. Package tray looks really good. No waters stains from what I can see. No undercoat it appears but who needs that if you only drive it 200 miles a year right? Quite the find sir! Curious what the blue wire from the battery to the Relay on the firewall is about? Do 72's have round dome lights?? What shape are the original tires in? Tread seems good but I would expect the sidewalls to have cracks. Definitely a good idea to change them up.

-

Was this a local car? Can't be too many originals left out there but you found one.

-

Can't seem to find that email Aaron. Has something changed? Sandy seems to have been able to get those dates off now so she can come. Pretty sure the car isn't going to be done in time.

-

Thanks Aaron. We will do what we can to attend wherever and whenever it happens. A much as I'd like to debut the new Monte at the western meet in Montana, the body shop progress is not going well so may not get it back in time to have it together to drive there. It's been there 4 months and less than half done. They just started on the driver's side. Thanks for the update. I'll keep the room booked until we know for sure what the plan ends up being.

-

Finally made it back to the garage today. Lower frame rail in trans cross member mounting area is 50 7/8 all the way along. No visible twists bends or other damage I can see that would make my mounting holes 54 1/4 instead of 53 5/8. The entire drive train was in a different 70 Monte and it all got swapped over when I got the 70 I have now. It had the original trans cross member and I was able to get the rubber and metal clamp system in this cars frame so that is what I was using for the 4l60 and it worked great. The other car I had to drill a hole in the frame and the cross member and just mounted it directly to the frame. Couldn't seem to get it to fit in the other car but went in easy on this car. Checked this cars body mounts and they look great. Almost think that had been changed in the past as you can read Chevrolet in raised letters on them. Somehow I doubt that was the way it came from the factory. Will get the tunnel cleaned up and clearanced tomm then test fit things again once I get my trans pan back from having a temp bung welded in. Once the tunnel is where I need it I can size things up for the mods to the cross member and get that going.

-

I can see those differences now that you mention it. I was so focused on the height issue I didn't see the angle and mounting tab differences. With the 4l80 you definitely need the increased angle the RCAE-4 gives you. When I first found this cross member issue I debated about just making a custom one but couldn't do that without having the trans fitted properly and having the headers attached, which needed some mods anyway, and towing it back and forth to a shop so started looking for premade ones. Didn't do as much research as you but with my distances between frame rails off, which I will look into when I get back there tomorrow, I would be customizing one anyway. At least when I get the tunnel mods done I can measure things up to widen the exhaust areas, raise the trans mount tab to minimize the gap and do it without removing the car from the garage. I can also see how the shifter is going to be affected by raising the tunnel to clear the tailstock so will be mindful of that when I get to that tomorrow. Your experience has been a great help. Thanks.

-

Got the g force cross member Monday and test fit it. The mounting holes are exactly 53 5/8 on center. My frame holes are 54 1/4 so I can bolt one side in and see the edge of the cross member support tab through the holes on the other side. Missed it by that much! I ordered the one for the 4l80 and the mounting tabs are higher than the one for the 700r4/4l60 which dramatically lowers it. I still have almost and inch of space between the bracket and cross member with the 1 5/16 mount in there and I still need to move the trans up in the tunnel. If the pictures on their site are correct it would seem the RCAE one would work better than the RCAE-4 for the 4l80 trans. I picked up a 2 inch energy suspension mount and will look into modifying this cross member. It mounts in the 2nd and 3rd holes from the back and is angled back from there to support the trans. If I widen the exhaust areas and narrow the trans mounting area I might have enough room to work with to keep the x pipe exhaust system. Once I finish clearancing the tunnel and get the trans positioned at the right angle I'll have a better idea how much space I have between the cross member and the mount. Extending the exhaust areas will raise it a bit but if I need more I'll move the mounting tabs down to raise it up and minimize the spacers. Widening the exhaust areas will also allow me to create a 54 1/4 distance I need between the mounting tab holes. What is the center to center distance between your mounting holes in the frame rails? If it isn't 53 5/8 I wonder where they come up with that number?

-

Thanks for posting them. Those articles are very helpfull. Shame I am going to loose the x pipe. Might loose it even if I use the original cross member becasue it is so far back. That Chevelle tunnel seems to provide them a bit more clearance to get the 3 degree angle. Mine is at 5 and hitting the speed sensor to do that. Don't have to get it back to 3 as I'm using EFI and can easily adjust my diff angle as I have adjustable uppers on it. They seem to be able to use the factory shifter cable as well. Mine seems reluctant to bend that much and avoid the speed sensor. Maybe lifting trans will help. Have you tried that 32 inch Shiftworks cable yet for fitment?

-

Holy smoke! Did this response up this morning but didn't hit submit before getting distracted and forgetting. Was looking forward to a reply but can't get one if ya don't send it silly! I contacted the folks that make the banjo fittings and have determined I do have the 1/4" ones so will order them up....likely get 2, just in case. I searched for Banjo fittings but didn't seem to be getting anywhere but also didn't search ebay specifically. I think Banjo fittings will be the best option so will order a set of those vs cutting and tapping the regular fitting to install an elbow. I was worried they were just going to be the regular fitting but the fact they made them with the extended part for the rear one is fantastic. I have the fittings spread apart so they should be the 1/4 NPSM fittings. Shame it may take up to a month to get to me according to them but extremely gratefull that they make them so I'll live with it. I am installing a TCI 6X behind a Mark 4 BBC. Supposedly the TCI 6X is the same case as the 4l80 but don't have one to check measurements myself. My measurements come from the 4l60 I removed where the rear mount is 22 1/2" back from the face of the trans and the mount on the TCI 6X I'm installing is 30 3/8". For confirmation sake give yours a measure and let us know what you find. I started this because I thought these trans were not that different and should be an easy swap but that extra length is a complicating factor. On the TCI website, among others, the mount position is only 26" but that is wrong. The mount is at the back of the tailshaft not the back of the body so the body and mount numbers are reversed. Spoke with TCI tech and got him to measure it with his Mgr and they came up with 31" (?) and will supposedly change it on their site. I only had 4 1/4" left to move the rubber and metal cap system to the rear bolt holes so even removing that system and mounting it to the frame directly still wouldn't have been enough so started looking for solutions and came up with the G force one. Found it on Summit and they had it in stock so got it ordered. The TCI one they make wasn't even made. They still said it would take 3 weeks to make it and get it sent out so I'm happy and hopefull the G force one was available right now and as I'm crossing my fingers, will fit right. I looked into the cable idea too late to get the shiftworks cable added to the G force order but that looks like a best solution to being able to continue to use the factory horseshoe shifter. I already have it converted over to work a 4 speed so just need the 32" cable. That factory cable just won't bend enough to get around the speed sensor and line up to mount the bracket correctly. I almost think a shorter one would work better but don't want to buy the factory length 30", the 29" for the Corvette or the 27" cable and have them be too short so will go with the longer and decide later if I could have gone with a shorter one. The 32" one is the one Shiftworks says works best to get around the speed sensor for a 4l80 install. I was hoping to modify the floor for the tailstock and not affect the shifter. Perhaps if I do it with it in place it will keep the mounting points the same while letting the floor move to clear the trans. Will do the check twice, or several times, before getting into that. The sensor and cooler lines shouldn't be a problem to move as there is nothing supported by it.

-

Nice job with the cross member mods. I looked at mine and figured it would require tubing mods as I didn't have room to move it 8 inches back from where it was for my 4l60. Hopefully the g force one will work properly. Do you have any info on what mods you did to make your 4l85 fit the tunnel? I'm looking at making an fittings with elbows to connect an trans cooling lines. Might have to make some dimples in the tunnel for them still. Have definite issues with the speed sensor connection. Trans is at 5° so tough to leave it at that angle. Without adding some height where the tail shaft mounts to the body of the teams, I will only gain 3/8 of an inch until that part hits the tunnel. What have you found in your installation effort?