snomobeelr

Members-

Posts

485 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Articles

Forums

Gallery

Events

Everything posted by snomobeelr

-

-

So I may have an issue. The original Motor mount is 2 1/2 wide and the Energy suspension is 31117G is 2 3/8 wide. I think the other energy suspension "3.1114G" is shorter and its 2 5/8 wide. So too much correct, and it is shorter?

-

Another dumb question. Im just changing the driver side engine Side mount. Where should I jack up the engine from ? at the balancer? Or too much stress on crank. I would think if I jacked it up with pice of wood from the bottom flat part of oil pan I would crush it? Am I overthinking it ?

-

ARH - American Racing Header - Reviews anyone currently running them?

snomobeelr replied to snomobeelr's topic in Engine Tech

So the passenger side is basically the same location to the proportioning valve as the Patriots were. I did address this concern when I ordered the headers. The lower rear control arm - horn is pretty tight. Gonna grind the horn away to get more clearance. -

Thanks guys , I know the mounts won't fix the header clearance. I was thinking since I have the headers off maybe swap the mount. The build has 7000 miles on it and they are stock type engine mounts with rubber. 7000 isn't much but I do hammer on her a lot. Figured it might help tighten it up the movement a little, maybe. So If I do go poly on the engine mount do I have to go poly on the trans too? Thanks again, I do appreciate it. Alan

-

Tom I wish I had seen those when I was putting the car together for exactly the reason your saying, one and done. I really just don't want to change the frame mounts at this stage. Not to mention it will prove my wife to be right. Again . 😬

-

Don't mean to pile up the threads. changing headers may need to change Motor mount. BBC . My drivers side header was a bit close to the proportioning valve. I knew there was a little movement . But after pulling the header out , and as Tom suggested in another thread I may need to change my motor mount. I think least the drivers side Motor Mount and better off doing it while headers are out . Unfortunately Im not going to go with the "Chris Alston chassis works" . I know the debate over the Poly and the rubbers far as vibration. I just want to make this as easy as possible and use the existing frame mount. I am leaning towards the Lakewood 24087 or the Energy Suspension. Does anyone know which Energy Suspension I should get is it the "Tall and Narrow - 31117G?. Or any other sugjestions? Its been a long time. I can do one side at a time right? Thanks everyone.

-

ARH - American Racing Header - Reviews anyone currently running them?

snomobeelr replied to snomobeelr's topic in Engine Tech

Those look really nice but I don't wanna re-invent the wheel . I know it's the nature of the beast , snowball effect. But every time I make a change I have to change 2 or 3 other things. Wondering if there is something that I can use the current frame side engine mount with. Don't think I can get in there to drill holes without lifting motor way up. I did not realize how much she was moving until I puled the driver side header out. But the new ARH doesn't sent appear to be as close. -

ARH - American Racing Header - Reviews anyone currently running them?

snomobeelr replied to snomobeelr's topic in Engine Tech

She is moving a little now. I thought there was always some movement? The current driver side header I can tell the engine is vibrating. What motor mounts would you suggest ? Something like - Lakewood 24087 ? -

ARH - American Racing Header - Reviews anyone currently running them?

snomobeelr replied to snomobeelr's topic in Engine Tech

So I tried again this morning with my sons help. Able to get passenger side in. No gasket yet, not fully tightened , just verifying they fit 1st. But she's real tight on the lower control arm ream mount (horn) barley fit a paint stir stick in there. Really nice headers, seem bigger than the 1 7/8 Patriots I just took off. I know nothing ever 100% , every car a bit different. Wasn't planning on a hammer. I wanna see how they both are prior to contacting ARM 1ST. Thanks guys !!! -

ARH - American Racing Header - Reviews anyone currently running them?

snomobeelr replied to snomobeelr's topic in Engine Tech

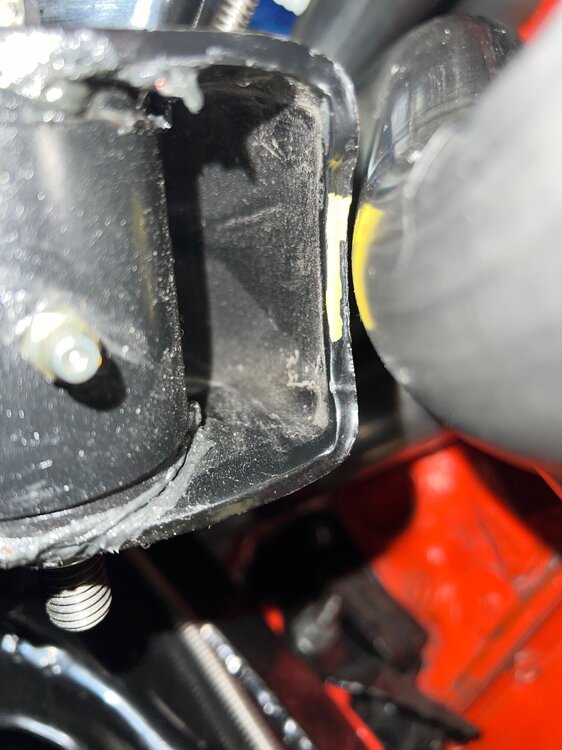

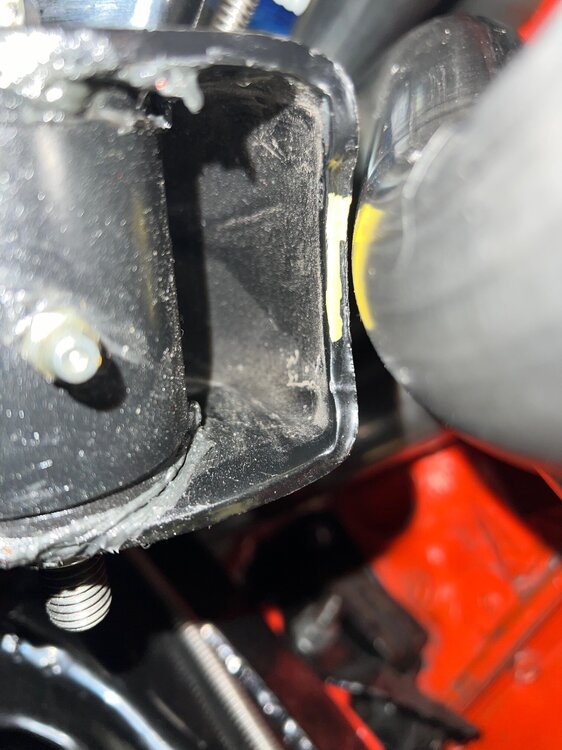

Im installing them from the bottom up. The passenger side is hitting the frame horn (last two pictures) can't get it all the way in position to bolt up. heres a pic of old and new. The pipes look thicker than the old. Thicker material? I ordered 1 7/8 and invoice says 1 7/8. -

ARH - American Racing Header - Reviews anyone currently running them?

snomobeelr replied to snomobeelr's topic in Engine Tech

Update , help? So I was exited the headers finally arrived. Issue on the passenger side she is hitting the frame horn and awfully close to frame. Was wondering if anyone had pictures of theirs? BBC 454 - 73 block. I bought the 1 7/8 headers. Brodix race rite heads with D-Port. Should be stock location. Stock motor mounts. Car used to be a 350. Don't remember if I changed the frame mounts for the motor or not? -

Max Width tires for the Rear?

snomobeelr replied to 72Custom's topic in General 70-72 Monte Carlo Forum

I was able to fit 295/50/15 WITH 15 X 10 5.5 in the rear only because I had installed the "Viking Coil over Shocks" in the rear. The rear shocks reposition the bottom of the shock inward towards the center of the dif about 1.5 inches. I did also trim the wheel well about an 1/8 inch too. -

I had the same issue with the dougs on the passenger side bb with th-400. Im gonna go with the ARH over the winter. I have the Patriot headers on they fit ok, but they hang too low.. .

-

Thats Awesome !!!!! Great job and Congrats !!!! thanks for sharing

-

Believe me I know.,Crazy right. This is my second year with it. Last weekend was 92 out stopped for gas, starts right up haven't had a single issue. No wrap and no shield. My proportioning valve I had to make a heat shield its on the frame and same thing, really freaking close...

-

John, I had the trans out and the old starter kinda chewed the teeth on the Flywheel. I believe I replaced it with the Pioneer Automotive 871003 - Pioneer SFI Certified Flex-plate. Are you sure you have the gear for the starter pulled out all the way? Its a bit of a pain to pull it out , I then used a flat head pop it all the way. https://www.summitracing.com/parts/pio-871003

-

I had the same issue with the 1st power master starter. The gear didn't come out enough to hit the flywheel right I had to go with the starter #9612 I believe. Its been great. I did have to grind some of the aluminum housing because it was so close to my headers... Here are some pics

-

Tire off? I took the tires off to get more room.

-

I have the Viking coil overs on all four corners. I bought mine directly from viking they were great to deal with... The main thing you can adjust the height of the car bottom line. You can do that with coil springs to a point but thats a PITA and you can't change it back to and forth or readjust. You can use the coil over from viking with stock control arms if you want. The rears bring the bottom shock mounts inward to the dif about 1.5 inches on each side . Thats good for getting a fatter tire back there. That was a bonus I did not know about. I run 245/60-15 in front and 295/50/15 in back. good luck

-

Congrats, Monte looks sweet. See your in Oswego. They started up a bunch of cruises in Northwest Burbs. Not sure Im ready to get out there 😏 https://mplions.org/cruise-nights/ https://www.facebook.com/meadowscruisenights/ https://www.flavorfrenzy.net/car-show

-

-

Torque Converter to Flywheel Torque spec

snomobeelr replied to snomobeelr's topic in Drivetrain Tech

I called ARP and they said per the spec sheet is Correct 80 ft lbs. The bolts I ordered also have a 1/4 inch shoulder. Hers a picture with my old flex plate and new torque converter. Second picture is with original bolt that was in old converter.If I measured correctly the torque converter hole is 7/16.. -

New Torque converter, rebuilt th400 and , new flex plate . This torque converter that was built for transmission it uses Bolt and nut it does not thread into the converter. Ordered ARP 230-7303 bolt set that 7- 1/16 x 20 thread and 1 1/4 long . Per ARP Torque value instructions they are to be torqued at 80 ft lbs. Seemed like a lot although I am no engineer. Flex pate to Crank was 60. Anyone else done this or know? Thanks ARP Torque Values.html