-

Posts

489 -

Joined

-

Last visited

Content Type

Profiles

Articles

Forums

Gallery

Events

Posts posted by MGD72Monte

-

-

Hi,

Sorry I didn't had time to answer about the vynil...

Actually mine is an aftermarket. The original vynil was in very bad condition.

I have never noticed the difference between original and aftermarket vynil

The difference we are talking about is that the original vinyl has a chrome border that runs above the drip rails exposing a ridge of paint (on this thread you can see it on the cars of Monteman, Murphy, Rod, Aaron, and Dennis) the aftermarket vinyl extends all the way to the drip rails like yours, Andreas old picture and mine). You say yours was replaced, did you see the original that came with the car and whether it went to the drip rails or not? Does your car have the vinyl code? Would be nice to solve this question.

...and thanks for considering the Monte in Monte Carlo challenge.

Thanks

-

Originally Posted By: MurphyI was wondering the same thing about the vinyl top, possibly just a 72 thing??

The vinyl tops like that are dealer or aftermarket installed, not factory.

Would the car still have the vinyl code on the tag? Mine does so I always thought someone just replaced the top and threw out the chrome but I have no evidence. If only the old girl could talk.

-

Fantastique Romain, combien pour faire le plein?

Peût-importe, l'aventure commence!

Oh and we're looking for a volunteer to make the trek and be the first to snap a pic of a Monte in Monte Carlo

. You would be the first as far as I know and it would make quite the trophy for the site. By the way, I see you have the same type of vinyl roof as mine, I'm starting to wonder if they were available like that.

. You would be the first as far as I know and it would make quite the trophy for the site. By the way, I see you have the same type of vinyl roof as mine, I'm starting to wonder if they were available like that. -

I agree with Sam, the back looks normal, front seems to be the issue, at it does seem higher than most. If it was mine I would be looking at droping the front instead of raising the back. The higher you go, the more wobbly the ride. Also, whatever you decide to change, I recommend an alignment after. I brought the rear on mine back down to stock height a few years ago and neglected to have that checked and found fish scaling on the front tires after a while.

Good luck

-

Sounds like your rear springs are just tired and need replacement. With all the right stock springs your car should sit level so if its not, there is probably something wrong. Adding a spacer doesn't make sense to me when springs are fairly inexpensive and having new ones should give you a better ride than spacers with sagging springs. My car (see sig pic) has fairly new stock springs and sits level. Looking forward to see a side pic of yours.

Good luck whatever you chose.

-

Hi Mark,

Good job and thanks for providing info on what I consider to be a fairly uncommon modification. I could not see the notes you mentioned so here are a few questions:

1. Looks like this doesn't not change the braking system at all, just the boost. Do I have that right or do you for example change the brake fluid type to silicone or any other elements of the system?

2. To install, do you need to remove all the stuff you seemed to have removed i.e. carb, rad, fuel pump, pulleys, distributor, headers, etc...

3. Where does the dedicated return line connect to on the ps pump?

4. Would you say the new feel of the pedal is like that of a modern car?

Thanks for your time

-

I'd be following the wires, especially any that you disturbed during your work. I once pinched a wire during re-assembly and as soon as I reconnected the battery I fried a fusable link so have a look to make sure none of the bundles are snaged.

Good luck

-

That's a good question and that's why it's good to have others with experience chime in. The info is from the book Drivelines book link which I used to rebuild my differential. In fairness the author does go on to say that his recommendations on break in may seem extreme to some but those are his recommendations for a long life, trouble free differential. I find in general these types of do-it-yourself books often provide more labour intensive processes, possibly because their audience did the work themselves and are willing to go the extra mile for that extra assurance that their hard work doesn't go to waste. I think his advice is also more focused on very high ratio sets which are not common on most cars you buy off the lot. However, some of his advice is consistent with general new car break in procedures in terms of top speed and taking it easy, something which some would not think of doing if they just rebuilt the diff and not the rest of the powertrain. The rest of the recommendations I think are just going that extra mile which the average new car buyer would not put up with.

-

My gear set was used so no extensive break in process was required, I just took it easy, but my book says that new gear sets with new bearings can generate an excessive amount of heat especially if it has a high ratio. It says that the gear manufacturer should recommend an oil type, be careful not to subject the transmission to full-throttle or aggressive acceleration for the first 500 miles. It also stresses that the first 100 miles are the most critical and therefore to keep the speed below 60 mph for the first 10 to 15 miles then let the axle cool for at least 30 mins, repeat this process until you reach 100 miles. Then it says to change the oil when you get to the first 500 miles to get rid of any metal debris from the break in process and to get rid of the break in phosphate coatings in the lube.

I'm sure others with personal experience with new sets will chime in.

Good luck

-

Great news Rob, glad you made it safely, I assume all the clots were caught by the filter and then could be removed.

-

Robert, thanks for the info, I'm not too keen on the non-dimmable part so that's good to know.

By the way you must have a steady hand and nerves of steel to be taking a pic of the dash at 145mph... and at night

!

! -

That's seems to make quite a difference, I've been considering doing something for mine as I also find those 194s to be quite dim. I assume the LEDs are dimmable with the headlight knob rheostat?

As far as your flexible circuit board goes it looks good to me. I've seen them in pretty bad shape and working. As long as the individual circuits are not cut you're good. I had a short in mine a few years back and was able to fix it by soldering in a splice from one I got in a junk yard. If you notice that some of the circuits are exposed, cover them up with some brush on (liquid) electrical tape, you don't want them to come into direct contact with any metal parts in the dash.

-

That's a worthy finishing touch to all the hard work you have put into this project. Simply spectacular!

-

As mentioned above 60ft.lbs is what you are looking for. Book I have calls for red loctite but as per Sam I like blue.

Welcome and congrats on the Monte

-

Good work!

-

I got my 10 bolt done with a 1/2" drive 18" breaker bar with a 24" pipe as an extension. I had to try numerous set ups to get some crush going. The set up that worked was to position the housing as it would sit in the car but on axle stands. The flange was prevented from turning by a home made flage holder with 24" long handle. The handle was resting on the ground so I did no have to hold it. The breaker bar assembly was set up on the pinion nut. With the bar slightly over the horizontal and with my left hand I was able to press down using my weight and gravity. My right hand was holding the housing to prevent it from jumping off the axle stands and as others have said check the torque often so you don't go over.

Good luck!

-

Some food for thought.

When you pay for the work you pay for the parts, plus a fat mark up by the shop plus you pay for somebody's time/skill/equipment/facilities to do the work for you. The shop also includes an amount in the price for future potential repairs and call it a warranty. So you've already lost the money up front, basically if there is warranty work, you've already paid for it in all the extra costs and keep in mind you will likely have to fight for the warranty to be honoured depending on the nature of the problem.... and you haven't gained any skills out of the process!

IMO here is when it might make sense to have someone do work for you:

1. You can't do it (lack of skills/tools/facilities/physically impossible) and can't address these issues for whatever reason.

2. You could probably do the work but it is so complex and the application so critical that you determine only a true professional/specialist can accomplish it to the performance standards you require.

3. You would have to take time off from your job to do the work and the lost revenues exceed the cost of having someone do the work for you.

4. You hate having to do the work and are willing to take the financial hit to avoid having to do it.

5. You are pressed for time and are willing to take the financial hit to get the work done faster than if you did it yourself.

6. You are so rich that the cost of the work is relatively insignificant and not worth your leisure time.

There might be other reasons but I don't believe a warranty is a good reason for what you are looking at doing with this car.

Good luck whatever you decide.

-

Good teardown progress, good luck with the restoration.

-

Like others have said the ideal scenario is frame off, sandblast and paint but some wire brushing and a good quality rust paint will work just fine. I wire brushed parts of my frame in the late 80s and the rust paint is still holding up. I also sprayed some corrosion control (Rustcheck & Krown) in the inside boxed areas.

Good luck whatever your choice

-

Sounds like you have a good plan in place. I did basically the same kind of complete overhaul a few years back. I bought a 1 1/8" front sway bar. I believe the original one is 1".

I also added a 1" bar for the rear. I believe the original one is 7/8".

Good luck

-

Hey Gonzo, that was my winter project last year... well sorta... I actually stuck with the existing gears (I love my 2.73s) and I also stuck with the C-clips. This is my album linky in case it might have something of use for you on the generic aspects of the rebuild. For the spacer question, I thought about a solid spacer vs a collapsible for a bit but decided against it after some reading and comments from transmission shops. Ease of assembly is one of the main factors. I think a solid spacer would be great if you could pick the right one off the start. One of the problems is the trial and error which is apparently required until you find the one that gives you the perfect preload although it is apparently a tougher set up so if you are planning on producing a lot of power some of the documentation says that under extremely high torques the collapsible spacer can deflect beyond its springback length and this can cause the load on the pinion nut to decrease and the nut can loosen. A solid spacer will not have this problem.

I got my ring and pinion installation kit from Jegs and had to get the OEM type collapsible spacer separately so I'm assuming it would be the same for solid spacers.

Good luck with your project and please keep us posted with pics.

-

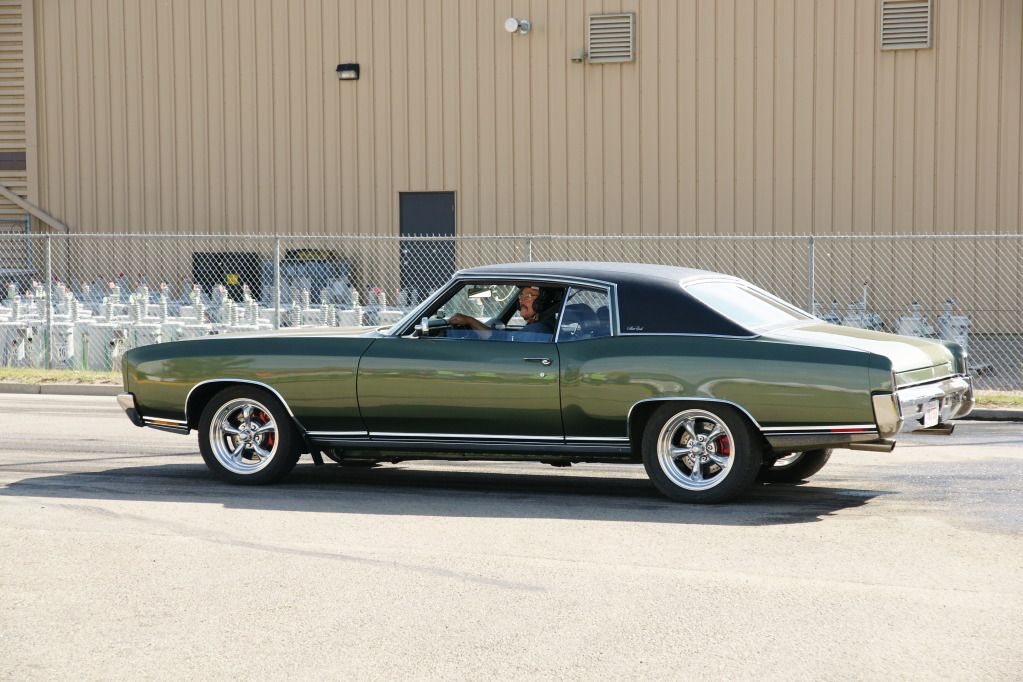

I agree, it sits perfectly and I really like that colour combo but for some reason I thought a 2" drop would be more noticeable. Mine is stock height with newish stock springs and I don't know if I can see any difference with this one

-

Thanks for the explanation Rob. Looks like you have found a good niche market

.

. Still wonder why the fiber glass hood they make for the Monte is not designed to look the same as the steel one you are making. Maybe they can't make those complex shapes out of fiber glass I guess. Your design looks so much more like something the factory would have done. IMO

-

Can someone tell me why there is apparently enough of a market for companies to make the fiberclass Monte hoods some of the members have but not make steel ones like this? I would think there would be more people buying this type, I must be missing something?

My Monte now at home in France

in General 70-72 Monte Carlo Forum

Posted

Salut Romain,

Thanks for that info. The code for vinyl roof in 1972 is Regular Production Option Accessory Option Code "C08" and can be found on the "Body Tag" which is located riveted under the hood. Check out this link <Body Tag Link> for more info on where to find the tag and what it looks like.