-

Posts

298 -

Joined

-

Last visited

-

Days Won

11

Content Type

Profiles

Articles

Forums

Gallery

Events

Posts posted by GatorDog72

-

-

As long as the housing stays with the car, replacing the ring and pinion with something aftermarket would be considered maintenance. Anyone combing over the car for original parts is never going to know you replaced the pinion. Don't go cheap on the rear end parts, get good stuff from a company like Moser or Strange Engineering. It's one of those jobs you don't want to do twice.

-

I just installed a brand new Holley 750 double pumper on my father's car. It runs pretty well right out of the box. It's installed on an F-word 351c with a 4 speed. I know.... it's not a Chevy, but were gonna pretend it is 😆. When I get the idle circuit dialed in where its happy, it will sneeze and backfire out of the carb when you give the throttle a good whack. (too lean) It goes away completely if I intentionally dial the idle circuit too rich, but then its blowing black clouds and smells like gas. I'm thinking my pump nozzles are way too small, it has a 28 in the front and a 31 in the rear. I'm trying not to guess in the dark, the whole nozzle tuning kit from Holley is almost $200. I'm thinking step up to a 31 nozzle in the front, 35 in the back. Any thoughts?

-

On 9/2/2021 at 8:54 PM, Dtret said:

Just for kicks after reading this I took a quick measurement of mine. After I tightened up all mounting bolts got the engine and transmission I measured, keep in mind I have no body on the car. Th400 has 2 transmission mount bolts I went at an angle to the top rail of the frame straight across and got a tickle over 23 inches on each side at the center of that sides mount bolt. Don’t know if it will help you or not.

That helps for sure! So mine is measuring 24 3/4” on the driver side and 25 1/4” on the passenger from the same points you measured from. Not only is it off center by 1/2”, the frame is really wide for some reason. I’ve never had an issue with crab walking or going straight at all. Nothing looks bent, other than the crossmember. The body sits square on the frame with even gaps on both sides. I’m totally confused 😐 why is it so wide???

-

That did not take you very long to get that engine slammed in there!! Looks great!!! Everything minty fresh. 🤩

-

-

Nothing like a brand new engine! Looks great!!

-

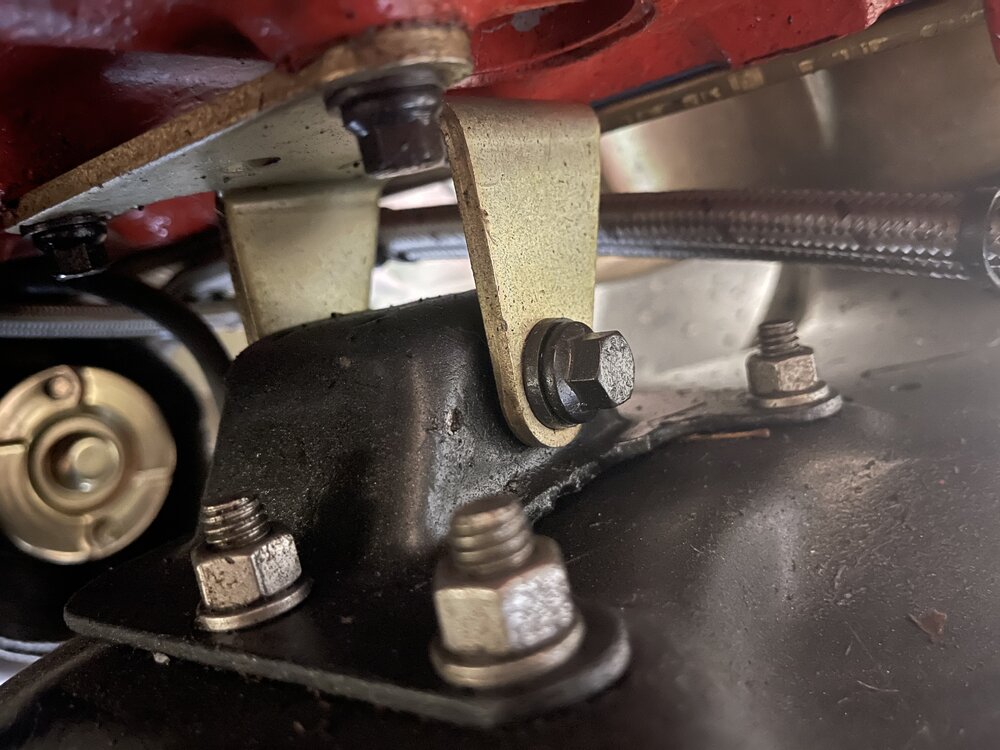

I think I've got a pretty big problem here. I took some measurements on the frame at several different points and the results are not good. Measuring across the crossmember, the measurement from the center of the bolt hole to bolt hole should be about 53 1/2"-ish. I'm measuring 54 1/4" at those points. I also measured the middle body mount holes center to center. Should be 53 1/2", mine measures 54". The front frame mounts center to center should be 52 3/8", mine measures 53 1/2". I'm going to go back through all these measurements to make sure its accurate. If its truly that far off, I have a really big problem.

-

The alignment holes are spot on. Body mounts look like they’ve already been replaced. It has to be something with either the front engine mounts or the rear trans mount/crossmember.

It’s probably worth noting that my rear end is an aftermarket Strange S60. Basically a Dana 60 with mounts to fit an A body. I checked it to make sure it’s square in the frame.

There may not even be a problem with the drivetrain alignment, it could just be a bad pinion angle. Just seems to me that the driveshaft should sit more in the center of the tunnel.

-

5 minutes ago, 420ponies said:

Drift pin the body to the chassis. Are you using poly mount for transmission? That's what I have with solid motor mounts.

I really hope the body is on the frame square because the roll cage goes through the floor and is solid welded to the frame. That would be an absolute nightmare if I ever had to move the body. Also it's a rubber trans mount. I'm going to switch it to poly because I've heard the solid ones will break the case. I never did replace the body mounts on the car. Only the front two where the core support mounts. I probably should have done that before the cage.....

-

My father and I will be there. I just called the hotel this morning, all taken care of.

Member Last Name: Palmer

Member First Name: Ryan

Club Website Screen Name: GatorDog72

Name of others in your party (please include ages of kids: John Palmer

Total number in your Party: 2

City: Syracuse

State: NY

Arrival Date: Thursday, 6/23/22

Departure Date: Sunday 6/26/22

Year of your Monte: '72

Color: Green/Black

Vinyl Top Yes/No: no

Vinyl Top Color:Class Registration: Modified

Hotel: Fairfield

Room Type Qn/Qn, King: QN/QN

Email Address: ryan.palmer45@yahoo.com

-

1

1

-

-

At this point, I don't really know for sure what is going on with it. It certainly doesn't look like the drivetrain is lined up straight to me. My plan of attack is to first replace that OEM crossmember with one that actually bolts solid to the frame. Hopefully that will solve the issue, it needs to be replaced anyway. I could just replace the tailshaft bushing but I want to know why it went bad in the first place.

-

-

19 minutes ago, dejh22 said:

You don't have a motor mount that is broken? I had a problem with a big block, it was a new rebuild and I run a steel motor mount on the torque side. The steel mount was a little taller then the ones I normally use.The engine was not sitting square and I ended up with what you have shown in the pics. It is a long shot but maybe a motor mount that is broke and the engine is sitting lower on one side.

Do you know what kind of mounts they were? I do happen to be running Moroso solid steel mounts in the front on both sides. The block is an oem 454. I don’t think they are broken, but I better look to make sure.

The strangest part is when I put a tape measure on the crossmember. I measured from the center bracket to the frame rails on either side. One side was 23 7/8” the other side was a touch short of 24 1/8”. That only equates to 3/16”- 1/4” off center, yet the driveshaft looks to be at least 1 1/2”- 2” off center from the tunnel. So maybe it is in the front end.

-

-

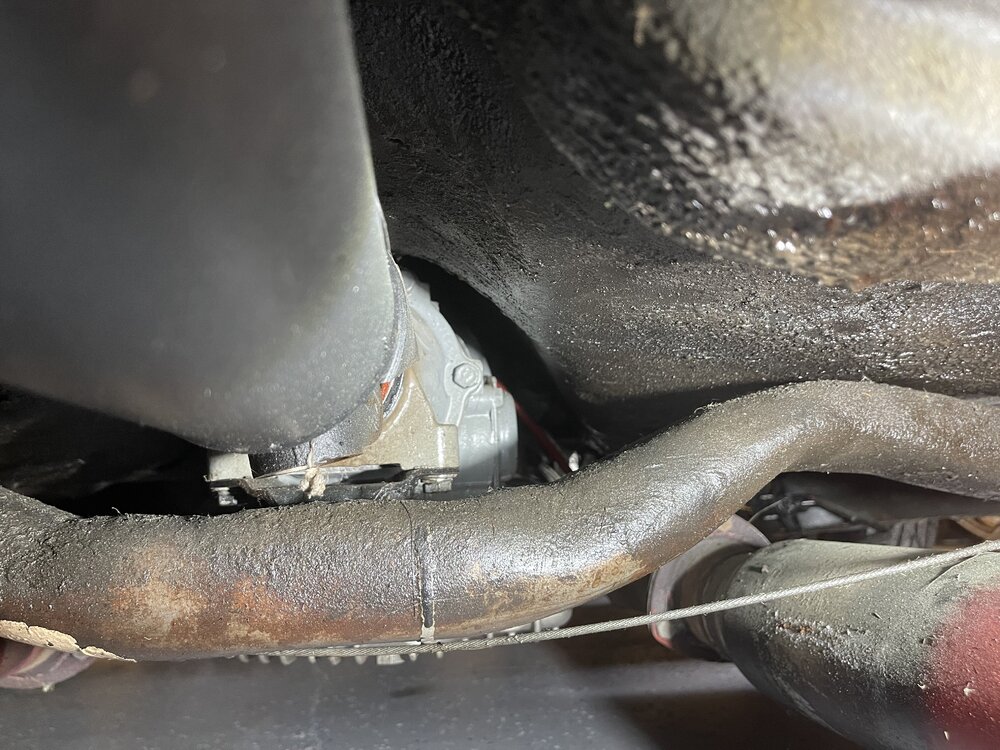

Does anyone have a picture of how their transmission tailshaft sits on the crossmember? Does it sit square in the middle of the trans tunnel, or slightly offset? I believe the crossmember in my car is bent way out of wack causing the driveline to be out of alignment. It got a really bad vibration after just a few hard launches. It wasted the tailshaft bushing in no time at all. It looks to be WAY off, there's about an inch on one side of the driveshaft to tunnel clearance, the other side I can stick my fist in it. I'll try to get a picture of it.

-

-

Bathtub works great, although I prefer the dishwasher!! 🤪😂😂😂

-

Thank you all for the kind words. It means a lot. Gator was definitely a character. We always said he won the doggy lottery. He lived the life of a king and will be remembered as the most gentle and loving pup that he was. I will miss him dearly.

-

My buddy Gator, the dog in my avatar sadly passed away this afternoon. I rescued him in April 2010. He was my best friend. He was always there through all the tough times. I miss him so much already. I was very attached to my dog, you can probably tell by my screen name. May you Rest In Peace my friend. 😢

-

8

8

-

-

I've got an MSD power grid controller and 7 series box. It sends spark to a locked out distributor. The mechanical timing curve can be adjusted right from the power grid on a laptop. The curve is based off RPM, not engine load. This setup works awesome for WOT racing, but I noticed the engine starts to get warm (about 220*) at part throttle cruise due to no vacuum advance. Can I use a map sensor with the power grid to advance ignition at part throttle cruise? All new vehicles use a map sensor to determine engine load. I couldn't find a way to do it. Am I missing something, or do I need a more capable ECU like a Terminator or Haltech? I don't care about fuel injection, I just want the ability to play with the ignition maps.

-

The secondaries are likely not opening at all. Its hard to find a good running q-jet, many of the rebuild kits are super cheap quality. If you don't care about keeping the car 100% original, just chuck the q-jet and get a holley. They're much less problematic.

-

Didn't make it out there this year.... Pops didn't trust his car to make it. He's having carburetor issues. Hope you guys stayed dry for the most part. It looked like a fun time despite the rain. I'll be better prepared for the next one!!

-

1

1

-

-

My father and I are trying to go for at least a couple hours. The weather looks like it doesn't want to cooperate. We will probably be in his Torino. My first gen won't be ready.

-

1

1

-

-

For stock-ish rebuilds I like Mahle. I also did a small block with summit brand pistons. They were super cheap. I think they were $85 for 8 pistons. Worked out nicely. I've used king bearings in my last two engines. Clevites work fine too, I have p series Clevite 77s on my big block.

More horsepower

in Engine Tech

Posted

Heads and a big roller cam will net some gains, but that rear gear is really holding you back. Swapping to a 3.42 gear ratio would make a world of difference. I have 4.10's in mine but highway cruising is not exactly efficient 😆