-

Posts

342 -

Joined

-

Last visited

Content Type

Profiles

Articles

Forums

Gallery

Events

Posts posted by Winston Wolf

-

-

I've been thinking of going to an electric fan setup on my 70. I'd like to retain the stock look as much as possible, and keep the tunnel. Has anyone accomplished this while going to electric? Figured I'd ask before I go through all the work and figure it out for myself.

-

Talk to Chris Kokkonis at CK Performance. He builds them for 9 second turbo Buicks.

-

Awesome thread! Great info and good reading.

I really want to put a 200r behind my mild 350 (replacing my TH350, 3.73 rear). My dilemma is I'm planning on replacing my motor next year with a 400+ cubic inch stroked motor (no power adders) and the engine builder doesn't think the 200r can handle the power.

Will a stout 200r that can handle 500-600 horsepower / torque work with my current and future set up?

It will, if it's built right. I would not use Bowtie OD for a high HP one though. I bought one from them years ago, shortly after it failed on me, we took it apart and found most of the parts they used were basically stock, not high performance. The OD solenoid never worked from the beginning, and their stall converters are far from "high performance". I'm not trying to rag on them, they are fine for street use cars, but I didn't have luck when I pored the coals to one. I view them like any old local trans rebuilder, but with a good website. Deal with someone that builds them for drag cars and is in to turbo Grand Nationals that have big power.

I've also read some info in this thread that I wouldn't consider 100% accurate. Learn about the trans and what the TV cable actually does. This will help you to understand how to adjust the pressure and have it shifting correctly. Also, there are better tv brackets than the one from bow tie. I think their geometry is a little off. I don't know how anybody is using 373 or higher gears with that overdrive, they must have dinky cams or stump puller big blocks; I had to go to 4:56's just to keep it from surging. And expect to pony up a grand if you want a real torque converter. You need a serious lock up clutch to lock it at full throttle when you have 500 hp. The 300$ ones people sell will last about 2 passes before that clutch burns up.

I'm only speaking from experience; I spent a lot of money to learn the hard way. Good luck.

-

750. It's not like you have a 350...

-

750

-

http://www.ckperformance.com/resources/GM2004RTRANSMISSIONS.html

http://www.converter.com/vigilante.htm

go with at least a 4.10 in the rear. I run a 4.56 with a 28" tire and it runs under 2100 at 55. Big stall for the strip, lock it up for cruising. There is NO COMPARISON driving one of these with an overdrive and low gears vs a 350/400 with medium (3.73) gears. Anyone who says you don't need one hasn't driven with it. Best thing I ever did to the car. The only reason to run a 3 speed vs 4 is because of money. If you can afford it, do it.

-

Try the solid mount on the driver side first. Cheap and easy to swap. I didn't notice any vibration change.

-

I wouldn't worry about knicking the carrier... If you do, sand or lightly file the knick down and move on.

-

Just cut the carrier bearings off with a dremel.

-

-

Originally Posted By: 72 LS5I wouldn't do it. You are going to spend money on tons of fittings, relay kit, wiring, pressure gauge, regulator, drilling holes in the car, and most of all, your time and the trips back and forth to the store.

A mechanical pump on a tame 383 would be fine, in my opinion.

X2. ^^^^^^

David

I think a mechanical pump on a hot 600 hp 427 or 434 SBC would be fine, in my opinion.

-

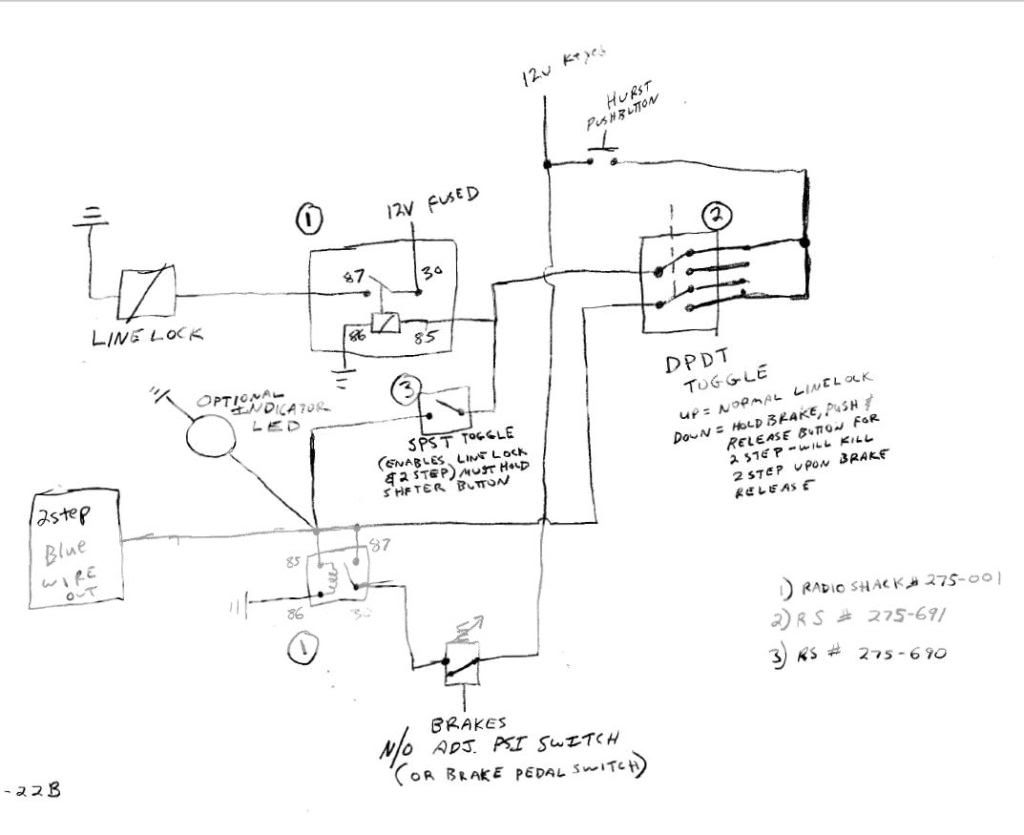

I installed the 2 step yesterday and wired it just as I show above. It does work as I designed. The only thing to note is the brake pressure switch should be between the master cyl and the line lock.

Too hard to really test on the street, since my car spins too easy, but I'll test it next year.

The adjustable pill works as advertised. I had it as low as 1500.

-

I found this from back in 96 when I was running the stock 350 block. It did around 280 hp at the wheels, ran 13.5 in the 1/4. The combo was: Stock bottom end, Trick Flow Twisted Wedge 180cc heads, Performer RPM intake and Edelbrock 600 carb. The cam with a Lunati Bracket master 2 cam, either the .460 lift or .480 lift one, I just can't remember anymore. The RPM cam would compare more to the bigger of the two. If you change the cam, I would use something other than the RPM cam.

Stick with a small runner head, keep the compression reasonable, put in an off the shelf Comp or Lunati cam and have fun. For what you are trying to do, most any aftermarket aluminum head will be just fine.

-

Chances are you have a regular 350 crank - 3.48" stroke.

If somebody put a stroker crank in your 350, chances are that it would have to be externally balanced (like the 400s were from the factory). When you use the 400 crank, you need the 400 balancer and flexplate. The balancer is weighted more on one side (of the inside by the hub) and the flexplate has a weight about the size of a pack of gum near the teeth. There are some exceptions such as when somebody has the crank itself balanced with some heavy metal so they can run a regular balancer and flexplate, but that's expensive and not too common.

I wouldn't say that is true. In fact you'd be hard pressed to find an externally balanced 383 or non stock 400 now-a-days. Summit lists qty 53 3.75" stroke 2 pc main crankshafts, of those, 47 are internally balanced. The 6 they have are all cheapy cast ones from 160 bucks to 250 bucks. When doing a 383, you started with a 350 and wouldn't want to buy a 400 balancer and flywheel, since you can use the 350 stuff with the correct crank.

Just don't want to send somebody down the wrong path.

-

A polished turd is still a turd. Best heads for the money are AFR or Profiler. Buy once, cry once.

How much HP are you trying to make?

I am assuming this is a SBC?

-

Here you go guys, this will allow you to leave off the 2 step and the footbrake, or the 2 step/line lock and just a release of a button. It will also have normal line lock functionality.

-

I took the car out again to try a few things.

Holding at 2k with just the line lock (you really have to jam the pedal hard) and releasing off the button, there is a delay before movement.

Holding at 2k rpms with the pedal, and releasing you get instant movement, however there is a delay in the brake switch, the brake booster must hold the pedal from coming back quickly. So the lights stay on for that split second also. Therefor, I don't think an additional switch off the brake pedal would be effective either.

I tested one of my Harleys for electrical response time when releasing the brake. They use a pressure switch in the brake line to run the brake lights. Those seem to work instantly as soon as you release the brake. I'm thinking now a pressure switch in the brake line is going to be the only way to get it to react fast enough, but I would like to install one and see how quick it really is.

I think a latching relay would also be better on the shifter button, then you just stage, hit the button once (with the brakes pushed down) and once you lift off the pedal that's it.

-

Sorry Justin I may have been confused as to what yo were asking. The LL is a summit. I have a 6al box that I haven't installed.

I saw the adjustable pill you can use on the two step

. I'm guessing when you plug two step into the 6al and activate the two step that the limiter circuit in the 6al would function the same by dropping different cylinders.

. I'm guessing when you plug two step into the 6al and activate the two step that the limiter circuit in the 6al would function the same by dropping different cylinders.My e-curve distrbutor has an adjustable rev limiter built in so I would be using the limiter circuit in the 6al for the two step only.

David

No, I understood. I am using a cheap Biondo. I'm wondering if a more expensive one like a Hurst would have a quicker release time. I might also try a microswitch off the brake pedal with a selector for mode. So operation with my shifter mounted button would be: toggle in pos 1 for burnout, line lock works as normal via shifter button. Toggle in pos 2, shifter button is wired in series with foot brake micro switch and supplies 12vdc to 2 step only. This would allow you to do the burnout as normal with the line lock, then flick a switch, pull up to the line, stage (brake pedal down as you always would footbrake race) hit and hold the button on the shifter and mash the gas. As soon as you lift off the brake pedal, it goes. Then you can let off the shifter button and continue the race. The 2 step would never be able to work unless both the brake pedal and shifter button were depressed.

As far as the high end limiter, that is about how I currently run it. I don't have a pill plugged into the 6AL, I use the rev limiter on my Ecurve for the high end limit also.

-

I don't have a digital 6 ignition, just the old style 6AL, but they have a 2 step which uses a pill for these. One nice thing is they have a low RPM adjustable pill, so you could get down to 1000 RPMs... MSD adjustable pill and 2 step for old 6al

My only concern would be if it pulls from all different cylinders like the new one, to avoid crank damage at the low RPMs...?

-

What brand did you have?

-

I don't think the converter is the issue, I think it's the line lock/brakes.

Simple test, hold the car at 2k with the brake pedal, just enough so that it doesn't move. Let off the brakes and moves instantly. Do the same with the line lock, and there is a significant delay before it moves....

Breese, can you try it and see what yours does in that test?

-

I took the car out to see what this would be like. I don't think think tying the line lock to the 2 step going to work. In order for the front brakes to be able to hold, even at 2k rpms, you really have to push the pedal HARD. It will hold it, but there is quite a delay from the time you release. Noticable, as in probably a half second. (remember, we are talking about hundreths in reaction times) You need much less brake pressure to hold it on the line with the pedal. The brakes don't release fast like a transbrake...

It's tough to exactly tell on the street if it will work well enough on the track, when the engine is under full power. With the slicks and WOT, maybe the delay will not be noticed.

Maybe Dave B's will work better, perhaps my line lock releases slower than his...?

-

Right, but what I'm saying is you have to take your foot off the brake at the same time you release the button, correct?

I want to hold the car on the line with the line lock only, so when you release the button it releases the brake and the rpms go. Only using the button, no foot.

-

I think I will do this too. I'm going to tie it into my line lock switch so I can have my foot off the brake. Then release button which kills the line lock and rpm limit.

Dave, it looks like you still hold the brake with your foot?

I watch my cousin launch off a trans brake and it's just too easy. This would be the next best thing without all the trans brake shock.

I have to see if I can hold the car at 2000 rpms with just the line lock. I tried some different launch RPM's last weekend, at 2800 it will actually push the front tires...but it does flash to 4000. I might need to install a 2nd line lock for the back brakes to help hold it.

Electric Fan

in Engine Tech

Posted

This is probably the way I would go, the ford fan. Do you have any pictures?