Blackhawk

-

Posts

249 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Articles

Forums

Gallery

Events

Posts posted by Blackhawk

-

-

Make sure that your caliper slide pins are clean, free of gouges or galling, and well lubed. I use Sil Glyde for caliper pins.

-

1

1

-

-

There's good information here:

https://www.firstgenmc.com/forums/index.php?/forum/21-modifiers/

https://ls1tech.com/forums/conversions-hybrids-28/

https://www.chevelles.com/forums/lsx-engine.141/

https://www.lt1swap.com/2000harness.htm

I used the stock PCM and had it reflashed to remove the ignition security, emissions, and the transmission mounted range selector, as well as calibrate the speed sensor for my tire size and rear end gears.

You have a TH400 for this, but is there any thought on using a 4L80E transmission? You would need to do some minor rewiring of the stock harness with an adapter like this, but you would have the strength of the TH400 with an overdrive gear. The stock PCM can have the transmission information swapped, which I believe you would need to do anyways for the older transmission to work.

-

Urethane with the proper primer for the area, whether it's the 3M stuff from a can or epoxy primer. A good coat of primer will make sure water never causes issues.

-

They're both on the driver's side, one behind the front wheel and the other in front of the rear wheel. They're round with a cut through them, like below:

To help the body move over I put a floor jack perpendicular to the frame and lift a bit on one of the floor braces and just barely lift it.

-

Did you make sure that the body is lined up on the frame? There are alignment holes on the driver's side that you can check with a drift pin.

-

I called over to Auto City on Friday because I need a tinted back window. They didn't even have those in stock, and said that they might show up in a few weeks. The local glass place that I was going to have do the install said they were able to get the glass though, we'll see if there's actually any stock since I'm hoping to get it installed in a few weeks. It must be the typical supply shortages that we're seeing everywhere these days.

-

I'm not sure how good AMD glass is, but it looks like this is available (or will be next week).

https://www.summitracing.com/parts/amd-660-3468-c/make/chevrolet/model/monte-carlo/year/1971

-

I'll have my dad check it out, it's at his place ~70 miles north of Minneapolis. I'll call him tonight. If that fails I do know a local guy who might have some; he has quite a few Monte Carlo parts. I'll PM you his number.

-

Andy, are you an OTR driver? I have an original clear rear window that I got with my door panels years ago. It has remnants of old, cheap tint on it and I need to look it over for scratches, but if it checks out you can have it if you ever make it to MN.

-

The ACI foams only have the vertical channels for the bolsters, no horizontal channels.

-

When I tried looking this up before I believe the stock covers weren't tied down with the horizontal listing. However, it looks good to have it partially pulled down. I'm in the middle of doing upper 70 bucket covers and I just put tension on that seam using zip ties, they didn't need to be pulled as tight as the side seams. You would have to cut the foam for a channel.

-

-

It looks like Flatline is part of the company that owns PUI, Right Stuff detailing, and Soffseal.

-

23 hours ago, SSpev said:

I'm researching for bucket seat covers. Are these right? or What are they from? I would expect a barn find to be likely original.

I do like the look.

I may be wrong, but the washer fluid jug looks a little too square and there should be a compressor on the driver's inner fender if it was a real barn find. I think they were just sharing a cool car.

-

Mine are inboard with no clearance issues. The collectors line up perfectly with the bends in the Chevelle transmission crossmember.

-

I would get 8" wide wheels with a 4.25" or 4.5" backspace to center the wheel in the wheel well. Corvette wheels typically cause issues unless the car is raised. Wheel Vintiques and Jegs have rally wheels available, Wheel Vintiques in 4.5" backspacing and Jegs in 4.25" backspacing (but also a dual bolt pattern).

-

1

1

-

-

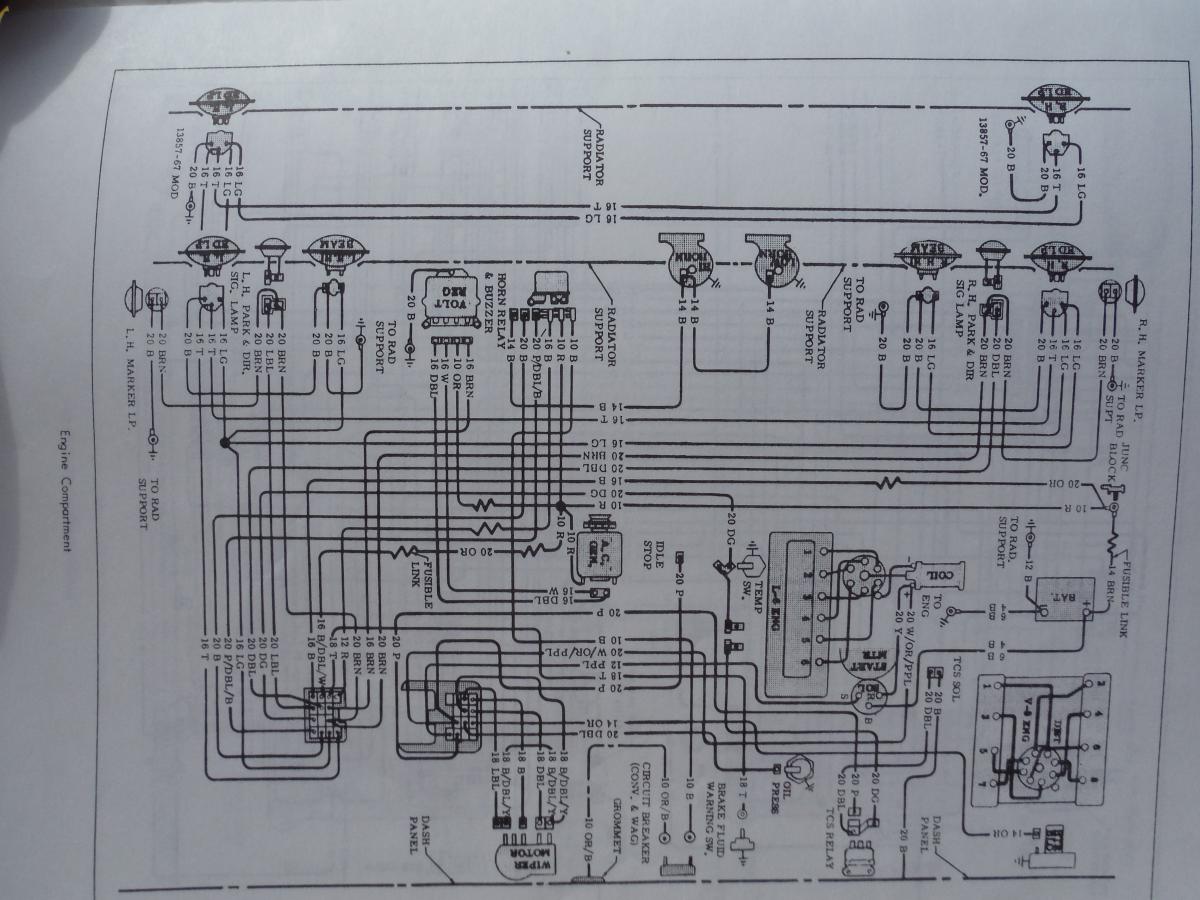

Make sure your wiring matches this. It's for a 1970 but the coil wiring should be identical no matter which year yours is. Test for continuity on the wire going from the coil to the fusebox. I would suspect that first if you only get power when cranking.

-

The Parts Place, Summit Racing, and Jegs have almost everything that Ground Up and OPGI carry but at a better price (and Summit/Jegs price match). I've only ordered window felts through OPGI/Restoparts (via Summit), and they don't seem to care too much about protective packaging.

-

1

1

-

-

Willie, do you have both the resistor wire from the bulkhead and the wire from the starter R terminal running to the coil? The wire coming from the R terminal gives full 12V to the coil when cranking, but it needs the reduced voltage coming from the resistor wire the rest of the time.

-

I have also had a few fittings that needed to be backed off and tightened again down the road.

-

If it's leaking at the brake lines it could be a poor seat, or even a metric seat. Check to see if there's a mark from the brake line not sitting centered on both the fitting and the brake line flare, and try pushing the brake line into the seat before tightening it rather than letting the threads pull it down. If all else fails you could try something like a flare gasket from Parker Hannifin, it's a copper gasket that fixes flare mismatch.

-

The Aeromotive universal fuel regulator is set up the same way. https://aeromotiveinc.com/product/universal-bypass-regulator/

I ended up running a 3/8" lines for both supply and return to make sure that the pressure can properly regulate. It doesn't look like Holley lists the limits of the regulators, but I believe that people have had issues running a bigger pump than a regulator can handle.

-

Summit Racing carries some OPGI products. It's usually close to the same price but they don't charge shipping.

-

1

1

-

-

Rock Auto is probably the best price for ACC carpet if you're fine with the stock style loop.

-

1

1

-

Ball joints

in Brakes and Suspension Tech

Posted

I prefer using a ball joint separator or tie rod puller for removing ball joints, especially because I'm running tall ball joints and there's a lot of space between the spindle and control arm. You can rent them for free from the auto parts store.