-

Posts

3,931 -

Joined

-

Last visited

-

Days Won

179

Content Type

Profiles

Articles

Forums

Gallery

Events

Posts posted by jft69z

-

-

Thx, was just curious. My car came with those, looked pretty old. Definitely a problem for the distribution valve. The prior owners simply unbolted it and bent it out of the way, crappy solution.

I also have a set of Super Comps from the old Monte I had. Driver side fit real good in that regard, pass side sits a little low though. I ended up cutting a couple of the tubes and tucking them up a bit for better ground clearance with some tube I had laying around, but wasn't the easiest solution. Those ARH headers Mark mentioned at the top are looking pretty good though.

-

1

1

-

-

Which Hookers do you have Mike, the Comp or Super Comp?

-

It's a LOT easier with the front fenders off Mark, lol (stirring the pot).

and 12 more bolts....poof, up, up and away goes the body...

-

1

1

-

-

Come on in, the water's warm....it'll be fun!!

-

2

2

-

-

It just snowballs from there, before you know it, the body will be off the frame, lol.

-

Think it's for the kickdown switch.

-

1

1

-

-

Could be a couple of things going on there. Check your PM, I sent you a number. Easier to talk than type, lol

-

Also, what leads you to believe cyl #1 is misfiring? Does that scanner have a misfire counter you can monitor?

-

Are the O2 sensors cycling (upstream)? They should be cycling between approx. .0 to.9 volts. The downstream should stay more steady around .45 v or above. Also, what are the LTFT numbers. (long term fuel trim).

-

Here's some info from GM regarding those codes. L96 is the heavy duty 6.0 L engine. The 8th digit of your VIN should be a "G"

-

3 hours ago, pab3589 said:

Sorry Joe,

If it makes you feel any better he doesn't really like us either , it's the farther you get from NYC ..LOL .. Thanks for keeping the lights on we still had staff working out that way. I am at the Comptrollers Office for NYS State Retirement.

Yeah, he's pretty much useless. Hopefully, I'll be talking to you in about 2 1/2 years when I'm planning to retire.

(NY Power Authority)

(NY Power Authority)

Edit: Just opened the email at work tonight, the NYPA employees in that area got the same message to stay home. Pretty sure the operators are working though.

-

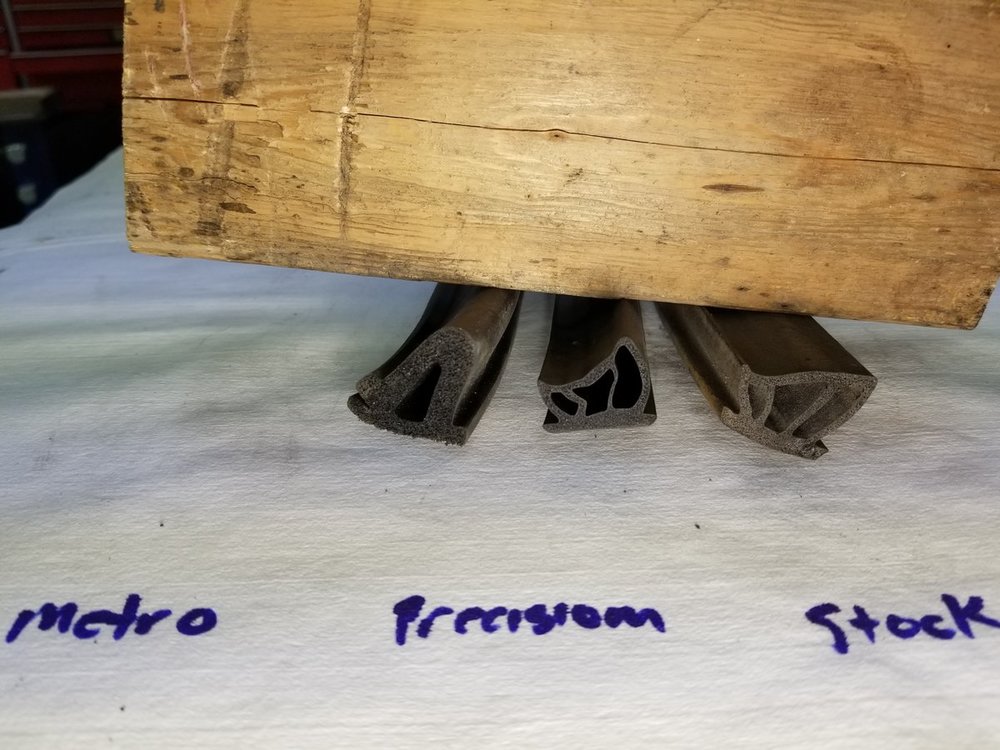

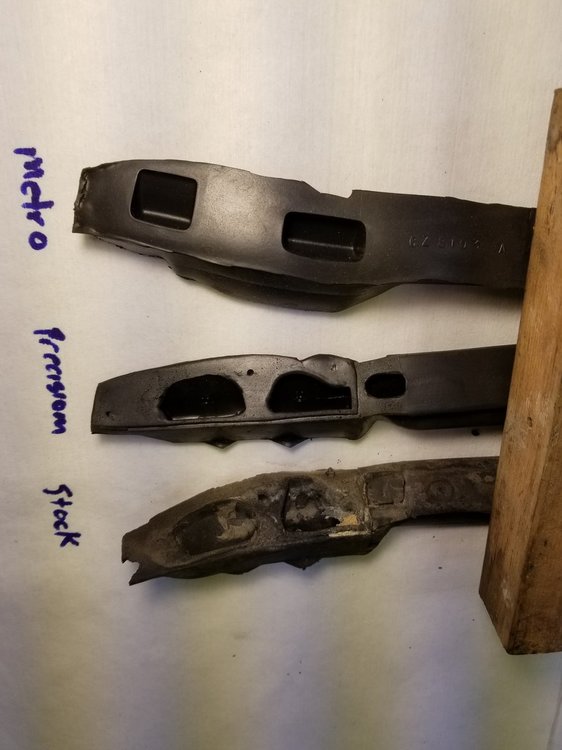

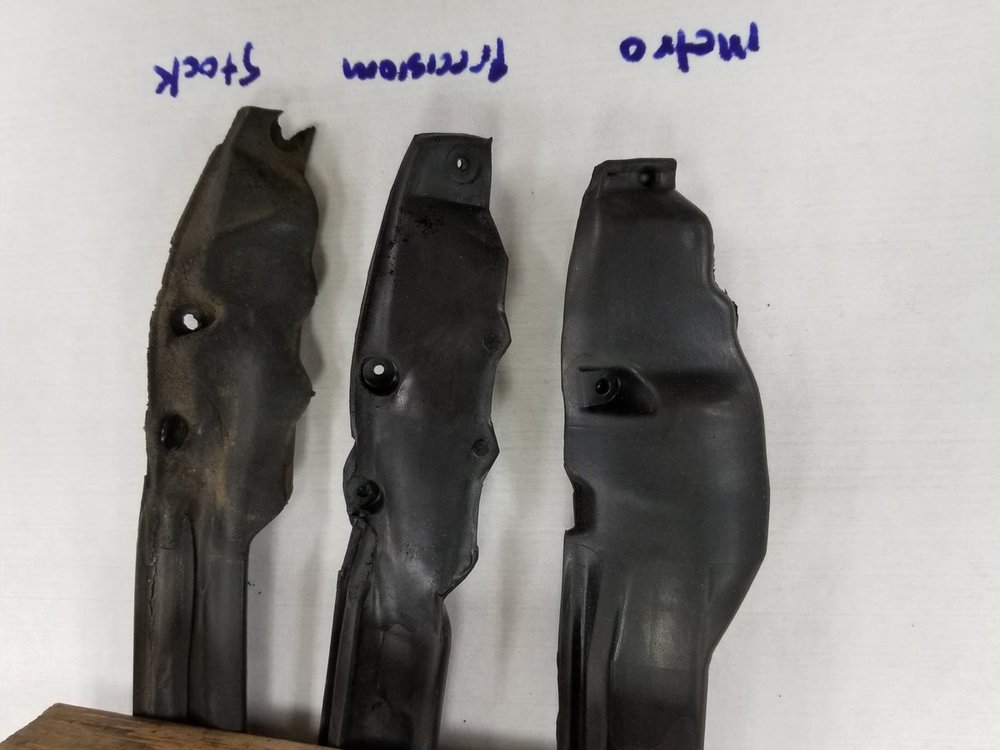

Here are more pics that show the difference between Precision, Stock & Metro Moulded

Hard to tell by the pics, but the Precision is much closer to stock in all aspects. The leading part near the hinge has the 3 holes, Metro-2. Cross section is clear to see, and the molded angle section is by far a better fit & nearly duplicated the OEM. The Metro is pretty stiff/firm overall as well compared to the other two.

-

Hey Patrick,

We're not so lucky on this side of the state, the governor hates us, lol. Unfortunately, we're considered 'essential personnel' and have to be at work (or stay at work if that's the case), exempt from travel bans, etc. The people are real selfish and seem to want their tv's, air conditioners, lights, etc around the clock and expect us to provide the electricity for them. Imagine, the nerve of them, lol.

-

38 minutes ago, Rob Peters said:

That's odd, the items I have gotten from Metro Moulded have been excellent fitting with no adjustment of hinges or latches to compensate for being too thick. Did you contact Metro to talk to them? Is it possible there was any kind of flaw in what you received?

rob

Not yet Rob, I'll call them later in the week after the other stuff from Precision comes to me.

The roof rail rubber they have is just one long section of a straight extrusion, nothing like the factory one that's also molded for that angled section. The cross section of it is solid and thicker than stock as well. The molded end of Precision's near the top door hinge is much closer to the stock one as well, the Metro one looks like a hot dog roll in comparison, lol. By all measures, the Precision part appears to be much closer to stock. I'm at work thru the night, but will take some pics and post the differences tomorrow.

-

Looks great, nice job!

BTW, thanks for the pics of the roof rail weatherstrip. I got a set from Metro Moulded, (not cheap either) and don't like how they fit at all. Way too thick & like you mentioned, not molded at the top forward corner area. It was like stuffing a sausage in there at the angle joint. I ordered a set from Precision and they came a couple of days ago. Much better and closer to the factory stuff in all regards.

Now I'm questioning everything I got from Metro, so I ordered a few more of their parts. Door set, trunk, & lock pillar seal. For the price of them, it's worth ordering to see if they're better. I'll post a couple of pics in my build thread down the road for comparison between the 2 companies.

Thanks again & keep up the good work.

-

Happy Thanksgiving to everyone, hope you all have a great holiday!

Also, hope you feel OK from the accident Tom, and are able to come out of it good, both physically & vehicle wise.

-

Thanks Jared, I need those. Figured they weren't available. Any part number for the inner ones with the 3 clips? I saw on an Oldsmobile site (when looking up these Fusick parts) that Soffseal 5023 may work? Has 2 clips, but manageable they said. Not listed on their site though.

-

So, the "replacement' tank came from Aeromotive today. The first one that came last week had a hole in the box & it rattled when holding the filler neck, like a broken spot weld or something. Sent the borescope down it but couldn't see anything. They agreed to send a new one out, but they say ,"they all rattle". Hmmmm…. so I'll have a rattle trap over every bump? They say when it has gas in it, it will be better. Not buying that excuse. The guy said it wasn't packed properly if I could see the neck though, and he'd see to it the new one got packed better.

So anyways, the new tank comes today, the hole in this box is even bigger. Pretty obvious the neck is still unprotected. Can't wait to get home from work to see how this one rattles. I'm sure getting whacked that hard on the neck to destroy the box to that degree won't have any negative effect on the inner structure....

. Called them to give a heads-up and send pics that my GF sent me, we'll see how this plays out.

. Called them to give a heads-up and send pics that my GF sent me, we'll see how this plays out.

Ironic that the damage is at the tape that says don't accept if damaged. Unfortunately, the delivery guy dropped it off and left. Looks like he kicked it out of the truck at 30 mph.

So far they've been great to deal with, so hopefully we can get this ironed out so I can run the fuel lines and keep moving towards the other mountains of stuff to do.

-

1

1

-

-

Fairly quiet day at work today, glad to help! 12 hours in front of computer screens, as long as the lights stay on, it's all good.

-

the 3/8" part is "pipe" sized. I'm at work now and can't measure it, but the ID of the -8AN fitting probably won't be much different than the ID of 3/8 pipe.

Edit: Quick search shows that the ID of a -8 AN fitting to be .39"

ID of sched 40, 3/8" pipe to be .495", sched 80 pipe to be .423" (this is the pipe itself, that would thread into your part, NOT the threaded fitting connection of your part). This all means, the ID of the -8AN fitting would still be smaller than the 3/8 pipe screwing into your Mallory pump. No problems as far as flow restriction (the -8AN would be the restriction in this case).

-

This will get you from 3/8 NPT to -8AN. Also available in natural or blue.

https://www.summitracing.com/parts/sum-220846b

90deg if you need it:

https://www.summitracing.com/parts/aer-fbm5037

(I just bought a box full of fittings to start plumbing my fuel & trans lines, had some of this stuff saved in my summit wish list. Aeroquip, summit, fragola, ICT, vibrant, etc. Various prices, some better than others for the same type of fitting.)

-

2 hours ago, gdubya said:

Also, what is the name of the ball on the linkage where the throttle cable attaches? picture attached

Throttle ball, ball stud, throttle ball stud, carburetor ball stud. Any of those will give you a good result with a google search.

-

Thank you!

-

I'm still going back thru those articles quite frequently as I'm going forward with some assembly now. They just had a new article last month I think. Sounds like they're getting close to actually firing up the car to see if that stuff is actually going to work. It better, Iol, or I bought an expensive transmission for nothing. That article (part 11) isn't online yet, too new. If it doesn't show up soon, I'll scan it & email it to you.

-

1

1

-

BB Headers

in Engine Tech

Posted

Mark, Tell me when, I'll be there!