Gush's monte

Members-

Posts

42 -

Joined

-

Last visited

-

Days Won

3

Other groups

Gush's monte last won the day on March 5 2020

Gush's monte had the most liked content!

Profile Information

-

Location

Holbrook, Massachusetts

-

Legal Name

John Gushue

-

Occupation

Manager

-

My Monte ('s)

1971 402 - Auto

Profile Fields

- Junior Member

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Gush's monte's Achievements

-

Thank you Dennis, I was able to remove the roller. I have the motor replaced on the regulator and tested. Waiting for a new roller that should arrive Monday. If it does not fit I can always weld the old one back on. It was definitely the motor that failed as all the teeth looked great when I took the motor apart. While I am waiting I am going to address the headliner at the sail panel that needs a couple of wrinkles smoothed out. When I put it in a couple of years ago I must not of got it tight enough.

-

Thank you Dennis, I tried wiring the regulator directly to the battery, but the regulator motor still just clicks. I think I will try either drilling out the guide roller pin, though I may need to cut off the part sticks out from the arm as it is folded over like a rivet, I read that is how the factory installed them. I looked online it looks like they may sell replacements. I am going to try to save it first by carefully cutting it off or drilling it off and welding it back on after I get the regulator out. Thank you for your help and the pictures.

-

Gush's monte started following Flooded every time I start it cold and Power window stuck down

-

Thank you Tom and Dennis. I have the back seat out, side panel and door vent out so I can have as much access to the area. The window is not bound up on the tracks, I can move it around. I have already unbolt the regulator to try to see if I can remove it from the window but with the window in the down position I can not get the regulator separated from the window. I have tried moving in all directions but run out of room before to roller on the regulator will get to the point of being able to remove it from the window slot it rides in. I have even removed the bottom window stop and removed the bottom over the vertical window track to try to get more room. When I restored the car a couple of years ago, I cleaned the tracks, put new lithium grease and rollers on the window. I wish I took the motors apart at that time but they were all working good. The clicking sound I hear does not sound like a gear noise, more like a solenoid click. I was thinking about prying the window regulator roller off so I can separate the regulator from the window, but think I would end up breaking it and not sure if I can find a replacement roller.

-

Has anyone run into having a rear quarter power window stuck in the down position? I have a new motor for it but can’t see how to remove the old. Looks like the window needs to be at least 1/2 way up to remove it from the regulator so that the motor can be replaced. I have 12.5 volts to the switch and the motor clicks when working the switch either direction. Tried multiple switches with same result. Also tried hitting the motor to see if it would start working again (like a starter) but no luck.

-

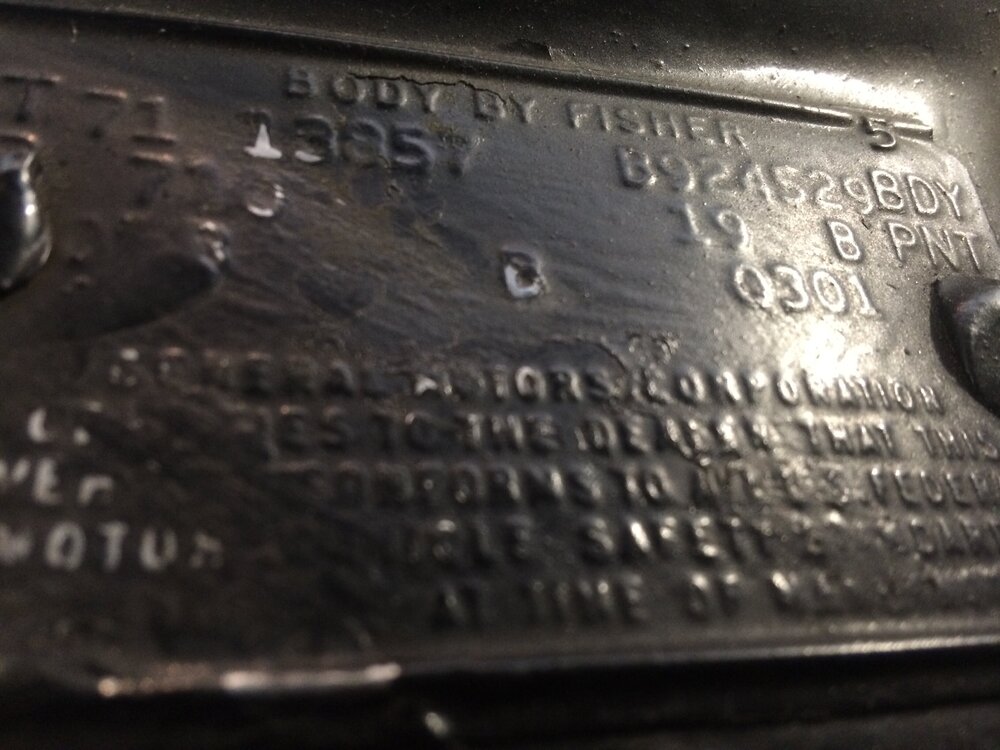

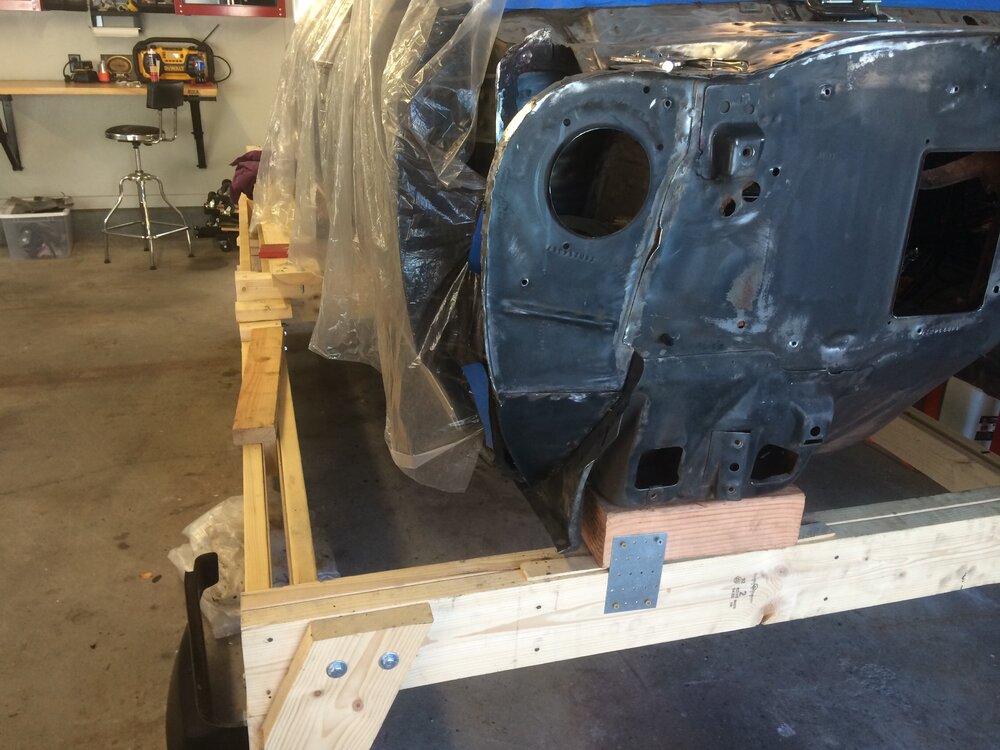

1970/71 Baltimore body tags

Gush's monte replied to Canuck's topic in General 70-72 Monte Carlo Forum

Here is a photo of my Baltimore built 71 402 automatic door tag. I also included picture of my firewall when I had the car apart during restoration. You can see the vin is upside down under the blower and AC cutouts. -

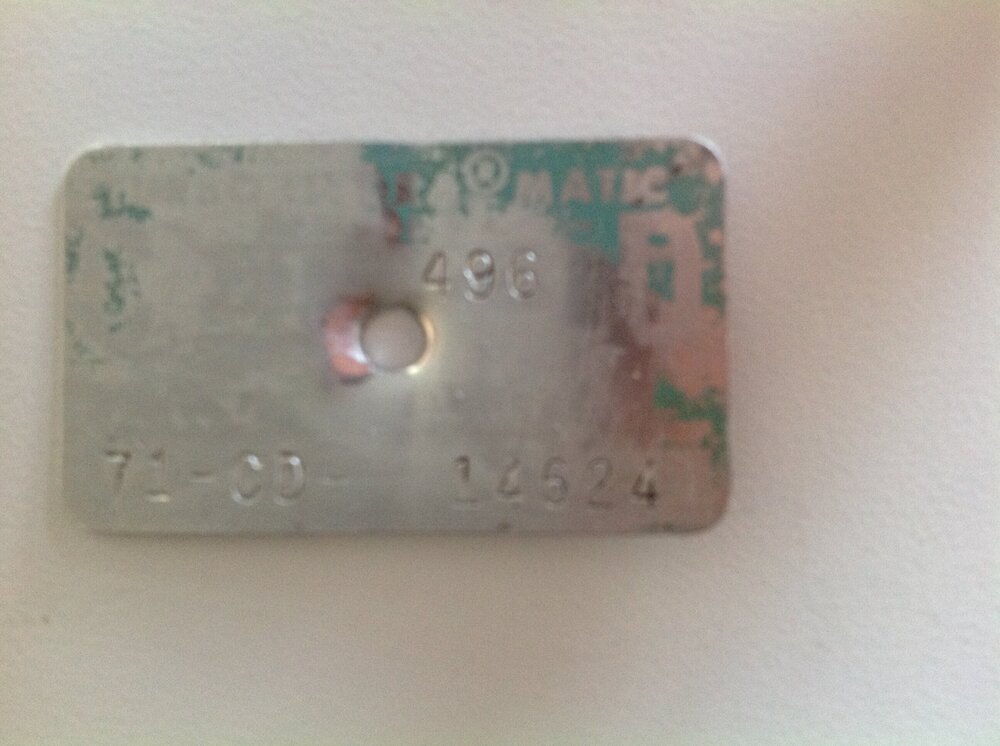

Images of transmission tags needed

Gush's monte replied to Canuck's topic in General 70-72 Monte Carlo Forum

-

Jim, car looks great. Looks like Jim Reid put the same cam in your motor that we put in mine. You will love it and yes the comp hydraulic roller lifters do make noise but as long as it is consistent (even sewing machine noise) you should be good. If you can hear one louder than the rest then you may want to look into it. I had an issue with a couple on my Chevelle’s motor but it was obvious noise problem. Comp warrantied the bad lifters, just a pain to change out. Hopefully see you at one of the cruise nights if the weather ever decides to cooperate.

-

Glad to help Frank, hopefully I will be getting to mine soon. If the weather ever cooperates maybe see you at the Plymouth show soon.

-

Also, on my Monte I have a bigger cam but run a Holley 750. I find it much easier to tune, easier to notice the change in each adjustment. Either carburetor will work but takes time to get the adjustment just right. When the carbs are set up on the Dyno they are set just to make the best power, not real world driving or throttle response you my want.

-

Dennis, I had a similar problem with the LS5 rebuild on my 1970 Chevelle. When we ran it on the Dyno with the original q-jet the secondaries would not open. The engine builder believed the problem was due to the high vacuum the engine was making not opening the secondaries. They drilled two holes in the throttle plates which allowed it to open at throttle on the Dyno and made good numbers 410 hp and 530tq. My build was stock except a baby hr cam 211 duration cut at a 112 Lisa and compression ratio of 9.8. Tuning the same carburetor to run well on the street has been a challenge. It would ping under load at high rpm, like it was running lean. Changing jets did not help. Also the transition to open the secondaries never felt right (always seemed to open to late). Any adjustment to the secondary spring showed no change. I have since got another q-jet on line and it ran great right out of the box. No pinging with 78 jets. In my research I think some of the passages in the q-jet core still have blockage. When I rebuilt the carb I let it sit in solvent overnight an used small brushes to clean out any passages but there are some in the core of the carburetor that are blind which you can’t get a brush into.talking to my engine builder he thinks a sonic cleaning my get the blind passages cleaned out. May try it over the winter.

-

Frank, look at the Legendary video for the 69 Chevelle covers as it shows how to install the bolster listing wires. The video is really good at showing all the steps needed to install their covers on 68-70 bucket seat covers as they are very similar in design. The bolster listings need to be installed in the correct position on top of the burlap and hog ringed to the seat springs. Then when you hog ring the seat cover listing wire to the seat listing wire it will pull the seat cover down to give it the factory bolster look. I will need to do the same with my 1970 Chevelle covers but won’t be doing them until sometime in August as I just received the seat foam for them.

-

Mike, there should be a gasket (either brass or nylon) between the large fuel filter fitting and the carburetor body. That was leaking on my Chevelle’s recently. I went with a nylon gasket as it sealed better than the brass. Be careful tightening it down ( should be a 1” wrench as the threads of the carburetor are prone to stripping).

-

Aaron, check to make sure your primary needles are not binding open or the spring is too strong for your engines vacuum to pull them down into the jets. If they are not pulled down into the jet, running on the power tip of the primary needle would explain running rich and not idling well when cold. Also check that the gasket is not interfering and not allowing the primary needles to be pulled down.

-

I was able to get my full trunk pan from below, had the trunk drop offs cut out but the quarters were still on the car. I had the body off frame also so no frame to get in the way.

-

Mike I use SS396 all the time for parts. I just verify that the part number is the same for a Chevelle and order it there. I am in Mass also and usually receive the parts within 2 days as they ship from Connecticut. For headers I went with Dougs with 1 3/4 tubes, they fit better than the Hooker Super Comps that we’re on my Monte when I bought it. The Dougs headers need to be messaged on one tube by the lower A arm mount but I have no issues changing the spark plugs. I have also heard good things about the figment of Herman 1 3/4 headers also.