-

Posts

78 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Articles

Forums

Gallery

Events

Everything posted by 70MC402

-

Last year I went from 3.31s to 3.73s and a true trac at the recommendation of 1of80 and I definitely drive it over 60 often, it woke the car up quite a bit and mines just a near stock 402. The deeper gearing makes the car much more responsive everywhere in the rpm range, and with 275/60/15s on the back 60 Is only like 25-2600 so still manageable for mileage, when im just cruising and not making pulls I can eek out a little over 12.3 mpg.

-

What did you do to your Monte Carlo today?

70MC402 replied to Canuck's topic in General 70-72 Monte Carlo Forum

Yeah he said the only mileage on them was rolling them around his shop a few times! It doesn’t look like they’ve even been mounted on wheels either. Once our weather warms up I’m going to drive the car in to work, make a pass and record my time with the Dragy I have and then swap tires and see how much different it is between the ET radial Pros and the et street SS for street pulls. -

What did you do to your Monte Carlo today?

70MC402 replied to Canuck's topic in General 70-72 Monte Carlo Forum

Today I bought a couple new used tires from a guy locally, they’re $520 a pair plus tax new and I paid $370 for them! I currently have a set of very used ET radial Pros, these will at-least allow me to drive in the rain, and be legal to drive on the road. -

What did you do to your Monte Carlo today?

70MC402 replied to Canuck's topic in General 70-72 Monte Carlo Forum

Made some pretty good progress on the fan shroud, first time tigging aluminum too, still need more seat time but I don’t think itll rattle apart too soon. I was able to get the top plate and fan mounting figured out today, also earlier this week I got the 454 block back from the machine shop to start deburring and clearancing for the 496 rotating kit. For now it’s all oiled and bagged as it’s 14 degrees and I don’t want to fire up the shop heat tonight. -

Not sure exactly what you’re going for with the car but when I went through my front end I went with AFCO low friction ball joints, they move with something like 2 inch pounds of rotational force, I’m not sure if it’s really something that affects just street driving but I corner somewhat hard in my car and figured any time you can get friction out of the steering it’ll just result in a better driving car. Just my two cents since they aren’t too much more expensive than like a moog.

-

There are numerous engines that are in the .040-.060 range for 489/496 builds. The best way to get this checked is to have your machine shop sonic check it for thickness, that’ll tell you just how much your casting can take, with taking into consideration possibly core shift.

-

What did you do to your Monte Carlo today?

70MC402 replied to Canuck's topic in General 70-72 Monte Carlo Forum

Started working on the electric fan conversion, got the direct drive fan and shroud out of the way, and the fan shroud cut out, going to a friends house this weekend with a brake to get it bent up before welding. Also started doing some measuring on my heads for the 496 I’m putting together. Oh and removed the 7/16ths knurled wheel studs and got the 1/2 inches screw in studs in! -

In the eleventh photo we can see the diagram of the electrical routing for the power windows, and in that diagram we can see the window switch supply voltage comes from the 14AWG red wire with white tracer. Do you know where that wire is fed it’s voltage from? I have the manual that these are pictured from and can’t find where this wire is supplied voltage. I’m trying to clean up some of the wiring in my engine bay and there is a 10 AWG orange wire with a black tracer that taps into the battery positive side of the horn relay then runs to a junction block on the firewall near the emergency brake mounting location, from there it attaches to what’s shown on the electrical diagram as the folding top switch, as my Monte does not have a folding top it attaches to a 1 to 3 splitter under the dash, gets wrapped up in the harness and then there is a 6 pin connector that runs down to the rear windows through the floor. It doesn’t show the orange as supplying the battery voltage to the windows but with this unplugged the windows do not operate.

-

Yep the way I had drawn out wiring it would be rear mount battery in a moroso box, vented to the outside of the car, from the negative i was going to weld a stud to the frame and bolt it on there, probably a section of 1/0 cable. The positive side would be a bit more tricky, from the battery it’ll attach to a master disconnect, with an extension rod ran out through the trunk near the bumper/tail lamp. From the disconnect it would go to the ford solenoid. The switched side going to the starter with another 1/0 cable, and the starter solenoid would be jumper down there, so only one wire headed down that way, ran inside the car to the firewall then punched through with a heavy duty grommet. Since it’s a starter cable it would not be fused but for safety it would have the ford style solenoid that only makes it hot when cranking, like the MAD electrical solenoid. On the constant hot side of the ford style solenoid would attach like a 1 or 2AWG wire with a 150-175 amp fuse, it’s fused this high because I’m converting from a 10DN alternator to a 12SI 100 amp from power master. But that will be ran inside the car as well up to either the inside or outside of the firewall, to a “buss bar distribution block” style junction block. This will power the electric fan which has its own fuse, the Alternator which won’t be fused other than the 150-175 at the back, and the rest of the stock battery supply wiring for the horn relay, and all the power to the fuse block. I’ll run a new wire from the ignition switch harness connector back to that ford solenoid for engine crank signal. I’m just not sure where I want to put that junction block. If I go outside the firewall I was thinking to keep it out of sight and clean looking by putting over by the E brake mount as I have wilwood disc brakes in the rear with no e brake setup and that assembly has been removed. I also have the stock 11 inch brake booster and was going to call around to Leed and Wilwood to see if a dual diaphragm 7 or 8 inch will provide enough stopping power to stop my 4000 lb boat while taking up less engine bay room/firewall space.

-

Good to know! At this point I have no plans of converting to EFI but glad I know that ahead of time if I do trunk mount the battery. My question is more how has anyone mounted the junction block where the battery cable to the rest of the positive voltage circuits- the alternator charging cable, the ignition switch supply circuit, electric fan supply voltage.

-

Like the title suggests has anyone relocated their battery to the rear to help shift weight in their car? A side benefit would be removing more from the engine compartment appearance wise. I have an idea of how I would do it with a master disconnect switch and a ford style remote solenoid so the starter cable isn’t fused or hot all the time and the rest of the positive battery cable including the alternator charging cable and ignition supply voltage would all be properly fused going forward. I was just curious if anyones done it on here and where you put the junction block for the positive cable to attach to the rest of the battery voltage circuits.

-

The machine shop we have here in town is pretty good, they’ve being building this same 496 build with a slightly bigger cam since the early 2000s, netting right around 600 horsepower and a bit more torque. I was going to have them do the intake port work to try to get into the 300-310 range for the intake ports, without getting too big with the port itself. They already did the 2.19/1.88 valves and valve job as well as some unshrouding in the combustion chamber. I bought the heads from them with the intent to have them finish them once I can afford to do so. I hadn’t done as much thought on the head gasket as I was waiting to figure out the exact thickness until I can get a burette on the heads and figure out the chamber size, then I was going to have the machine shop 0 deck the block and go for a .040 quench to try to help with detonation. With that compression and iron heads do you have any issues with detonation? The gear that I have in it now is a 3.73, true trac rear diff with 33 spline axles. Chromoly front and rear yoke and a better driveshaft from a local shop. I’m not sure what converter yet, I was going to get the engine together and that way I have the dyno to refer to and call around. I’ve heard ATI, PTC, Jake’s, and a handful other places are all reputable.

-

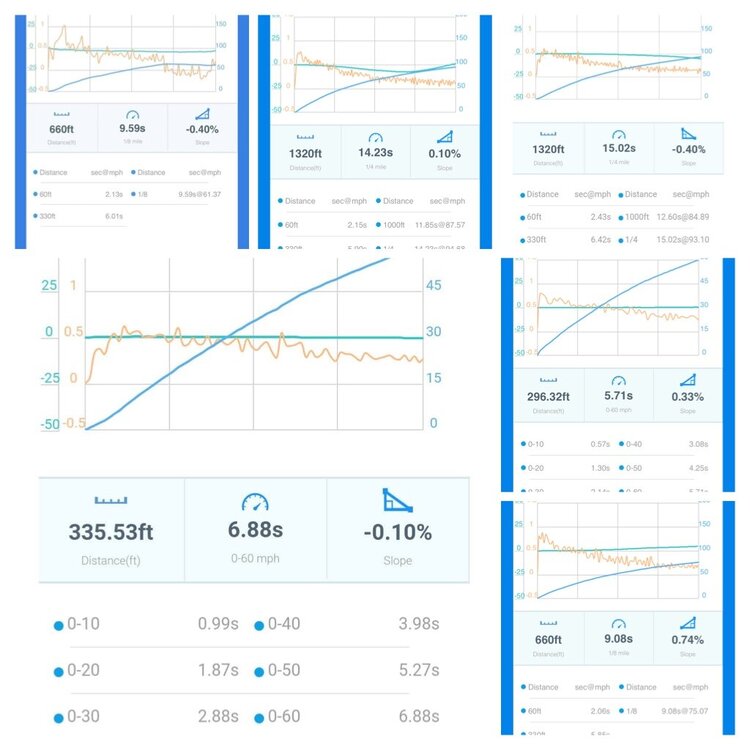

That’s awesome, I got a dragy earlier this year for my 402/400/12 bolt 70 Monte. Basically stock engine and headers it was running 15.1x’s quarter and 2.5x’s 60 foot on the street. Changed from some worn out 255/70/15 BFGs to a pair of used 275/60/15 MT-ET radial pros and dropped to 2.06 60ft and 14.23 quarter just by learning how to launch and drive the car. I’m putting together a 496 for mine too, 049 heads, comp .601/6.10 custom hydraulic roller cam and 9.5:1 scat rotating kit. I can only hope it’ll run like yours!

-

I believe what he is saying is he turned the steering wheel lock to lock 15 times, to bleed the power steering. Not that he has to turn it 15 times in order to reach lock to lock. The fitment may be what’s causing the excessive steering effort, find one for our vehicles and retest, you know the pump worked before as the old gear box didn’t have trouble turning one way.

-

2 1/2" mandrel bent stainless exhaust for SS

70MC402 replied to Grant MacPherson's topic in Engine Tech

I have the pypes 2 1/2 with an X and I would recommend to not utilize the X pipe. Even on a hoist it was a hassle to install with hooker headers. Still has some drone at idle but not as bad as before. I had the street pros on for awhile but it was too quiet for me pretty much anywhere in the rpm band. -

454 oil pan replacement not pulling the engine?

70MC402 replied to Grant MacPherson's topic in Engine Tech

I tried doing this about 3 years ago with a 402. I would say im comfortable with atleast your average amount of sketch as far as wedging the the engine on a 2x4 but I ended up pulling the engine because I didnt have enough height to get the pan down and out. -

Do they advertise any torque estimates? Having torque is probably what you'll feel more often than not unless youre spending alot of time above 4000 rpm. So building something to push our 4000 lb bricks out of the gate is probably better than trying to make a 7000 rpm screamer. That way itll really pull when you add a deeper gear.

-

Did you ever try the 295s on the 15x8 5.5 backspacing. Looking at buying a set of 295/55/15 MT ET SS' tires and fitting them on wheels with the previously mentioned wheel configuration. Measuring my wheel opening and axle flange distance from the inner fender it seems like a 5.5 backspacing centers the tire in the opening almost perfectly with an 8 inch wheel, just curious is you did it.

-

You can rebuild your rear end for alot less than buying heads, a cam, intake and all the gaskets. Changing to like a 3.31 or a 3.55 would seriously wake up the car. 3.31s would be better if you like driving on the highway like you said above. How much power is the RPM kit supposed to make over the Performer kit?

-

A deeper gear will make the car more responsive at all RPM, went from 3.31s to 3.73s last winter and it woke my car up. Only downside as people posted above is the reduced mileage. If you do change it over it would be a good time to look into a truetrac differential for improved traction. I second the roller cam comment above. The rollers allow much more aggressive ramps which typically means more power. When you spec out a cam make sure whatever springs youre using have enough open pressure to close that valve back up.

-

What kind of times does the Pandemic Monte What kind if time does the Pandemic Monte run?

-

Right now the KYB is in the front, i have some ACdelco load assist shocks that i bought when the car had the stock springs under the rear and i needed the height. Theyre probably too stiff now. I guess the big reason I was looking into the no hop bars is because on quite a few of the A Body and Chevelle forums they talk about how moving the instant center to the anti slack line of the tires helps the car really plant the rear end. I guess im not really sure if im worried about the look of the launch as long as it moves out well. I'll start with the tire pressure though. Thanks for the advice!

-

Sounds like a plan, I gotta get some different wheels on the back for 275s, i had to trim the quarters to get the tires to fit with a person in the back seat because with my rear end build the rear grew a bit. It would be easy if I could just make up my mind on what wheels!! Lol. Are you tslking the ETstreet radials? I had been looking at the ET Street SS'? I was thinking a set of adjustable shocks would be another good step, or coilovers for the height adjustment. Are you saying that adjusting the upper bars and causing the body to lift is a bad thing for weight transfer? Is that why so many companies drop the rear of the lower arm down now? I do have an anti roll bar on the bottom arms, its just bolted to them not to the body though. The front has stock arms with new bushings, afco ball joints, a 1 inch drop spring from UMI (actually raised the car up some from the original worn springs with the thread in spreaders) and KYB shocks.

-

Hello everyone, since i got my rear end rebuilt this past spring and its got the Truetrac ive been trying to figure out the launch nd get the car to really move out, right now its just been on the street, im not trying to be the fastest thing on land just want to get going a little quicker. The cars got a very mild cam (212/218) and a edelbrock performer with headers so I would guess its probably pretty close to stock power but it still spins them. Right now its got new UMI upper and lower tubular control arms in the rear, new stock height UMI springs and some ACdelco load assist shocks. The tires are 255/70/15 Be Goodrich T/As. Ive been looking into the control arm relocation kits, originally the ones that adjust the upper arms and either bring the rear up or front down to move the instant center rearward. Ive seen quite a few lower control arm brackets to move the lower control arm mounting lower, does anyone have any experience with either of the recolating brackets and experience with how they help plant the rear end. Thanks in advance for all the help!

-

Since i do more work on current era vehicles, I work at a dealer, my knowledge on the transmission kickdown is limited. As far as the throttle cable Lokar and a few other companies make universal cables that you cut to length. Thats an option. Another if youre good with metal fabrication is to make a bracket that comes off the carb thats further from the carburetor. Once the throttle cable length is sorted and you have good throttle action you should be able to press the "clip" in, and adjust the cable. Seeing that you have no shift i believe lengthening the cable would adjust your kickdown the right way. Hopefully some of the more seasoned members can chime in with experience.