-

Posts

893 -

Joined

-

Last visited

-

Days Won

43

Content Type

Profiles

Articles

Forums

Gallery

Events

Everything posted by Paul Bell

-

Sorry, actually, I don't like it. I'm concerned what happens when you turn it. It might stay up but I don't think it'll be stable enough to really work on it.

-

I installed these. They didn't seem to fit very well, I trimmed them and had to add the J-nuts. Bolt 5 is in to the chassis. After driving the car for a few hundred miles, one shattered. I suppose there was some movement between the body and the frame.

-

While I have everything apart, I'd like to replace my rag joint. 1971 car, original power steering box. Does it have the 13/16" 31 spline input shaft OR 3/4" 25 spline input shaft?

-

I heard a while ago that they were a pretty good match. However, I've never needed or handled any of it. Larrys advice sounds good.

-

That looks waayyyy better that the 25+ year old Hooker SC headers I had!

-

You folks that have the ARH, how's your number 8 spark plug accessibility with air conditioning? With what primary tube size?

-

What did you do to your Monte Carlo today?

Paul Bell replied to Canuck's topic in General 70-72 Monte Carlo Forum

-

If the driver's door won't close, the frame under it is bowed. I'd say it can't be repaired but it'll have some decent parts for somebody restoring another 70.

-

What did you do to your Monte Carlo today?

Paul Bell replied to Canuck's topic in General 70-72 Monte Carlo Forum

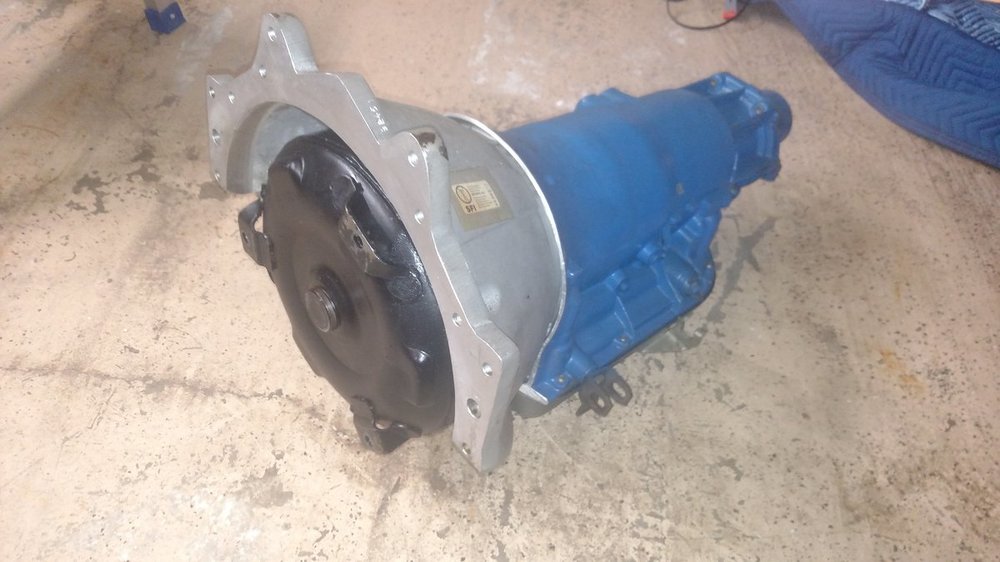

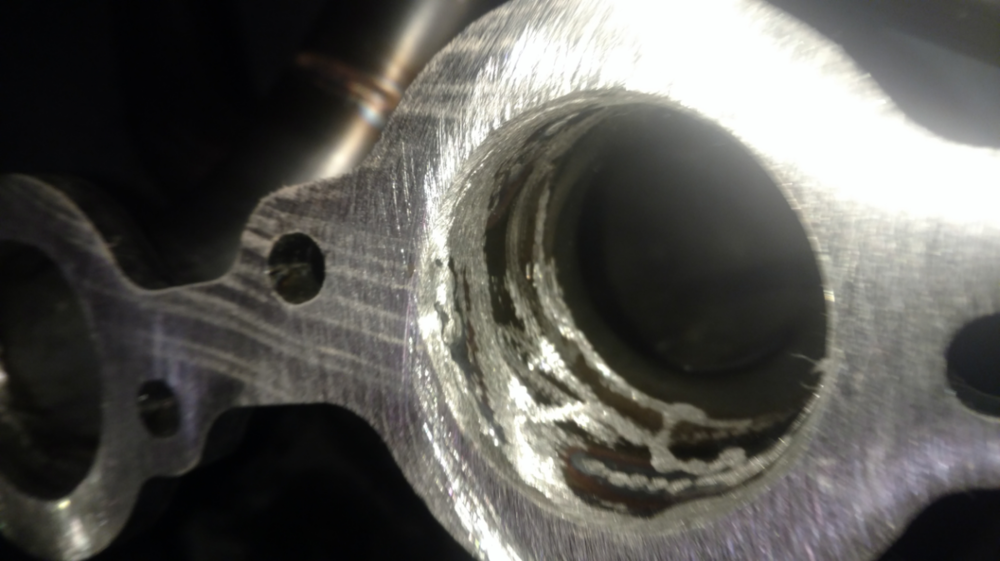

Mark, I installed that bellhousing many years ago, I cut the transmission myself-almost perfectly straight. The current version of it has some sort of O-ring around the pump bolts to seal them. Be aware you'll need a smaller than stock torque converter and there's no way to mount a torque converter cover. -

I believe most aftermarket crankshafts are internally balanced. Whichever way it is, you'll still need a shop to balance your rotating assembly.

-

What did you do to your Monte Carlo today?

Paul Bell replied to Canuck's topic in General 70-72 Monte Carlo Forum

Block is honed, washed again and primed and painted. Next up is checking main bearing clearances and installing cam bearings. Baby steps. -

I got one because I went to pick up my headers without confirming they were ready and they felt bad I took the trip out there. I'll be going back to have my o2 bungs welded in after I confirm where I want them.

-

-

We have a member here with these headers, 2 inch primaries I believe, and he has 3/8" raised exhaust ports. I don't know what control arms he has. I also have raised ports but I have aftermarket arms. And I won't be installing the headers or even the engine until springtime.

-

Perhaps. But they were still short handed and as I already went there to pick them up and left empty handed (my fault), they were rushing to get my order done. They called at 10am to say they were ready. It's about the headers to me, even if the clamps were correct, header companies furnish the narrow band clamps which I wouldn't use anyway.

-

Joe, no couplings. Just what's here: Warranty card; 2 stickers; 12 pt bolts 2 clamps-that I now notice are for ball couplings AND they're 3" so they're useless to me. I'll be getting my own flat band clamps.

-

There's some roughness where the bender's collar grabbed the tubing. I'll knock it down with some Scotch Bright. While these headers are exactly as I expected them, they can use a little buffing up. I was originally told the collector was ball and socket design and they would include a coupling, they are not, they are slip-fit, which I kinda preferred. They asked what port shape and size my heads had so for now, I'll assume they match. The collectors have the merge spike in them. As discussed, they do not include gaskets. They do include a pair of clamps for the collectors and header to head bolts-which I'll not use because I stud my headers. After I do some mock-up, I'll return to ARH to have o2 bungs welded in.

-

OK, I'm gonna go with what Joe said, that the stamper got the letters swapped when he stamped it. The "CR" code would be a 1968 rear with the 3:07 ratio and the casting number. It should measure 61.21 inches.

-

Yessir Todd, if the balancer has the weight, the flexplate should also have a weight.

-

That could be Joe. Tommy, while you're at it, measure how wide it is from axle flange face to axle flange face. Here's some numbers: Widths: 1964 - 1967: 60.5 inches 1968 - 1972: 61.25 inches Casting numbers found to be the most prevalent in Chevelle 12-bolt rear ends: 1965 Chevelle 3859140N 1966 Chevelle 3875745N 1967 Chevelle 3894939NF 68-69 Chevelle 3917124NF 1969 Chevelle 3959038NF 70-72 Chevelle 3969278NF

-

From the "K", I can say this rear was manufactured by McKinnon Industries. Tommy, see if you can get the casting number. It's on the front webbing of the cast center section.

-

I'm working on it, it's a good challenge.

-

Well that's definitely a Chevy car 12 bolt rear. Truck 12 bolts had a different cover.

-

Yeah Darren, I saw that code in Olds lists that's why I wanna see the cover.