-

Posts

74 -

Joined

-

Last visited

Content Type

Profiles

Articles

Forums

Gallery

Events

Everything posted by Bob Hansen

-

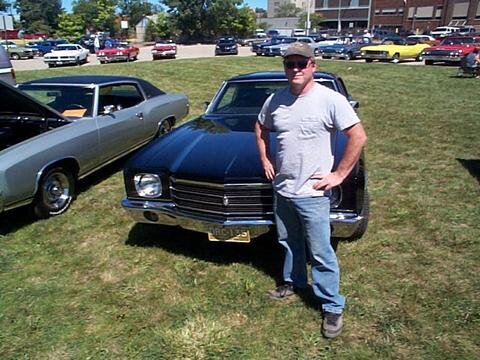

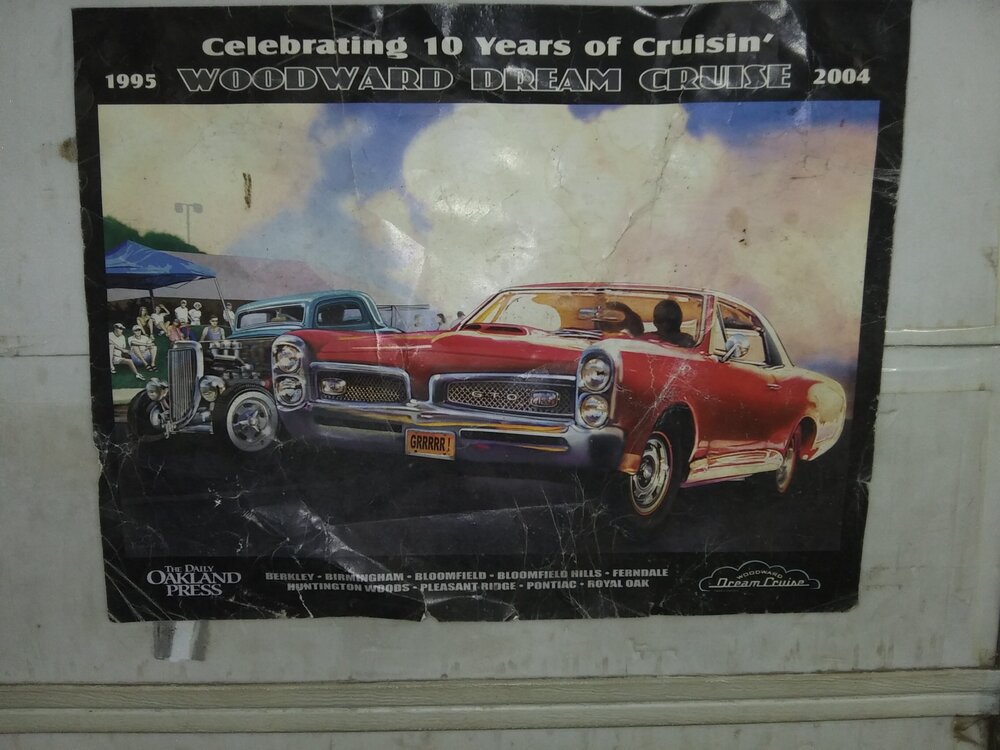

Since I didn''t get a response the above poster was from the 2004 Eastern Meet in S.E. Michigan at the Woodward Dream Cruise

-

Just joined today - SE Michigan

Bob Hansen replied to In the market for a 72 MC's topic in New Members

Welcome fellow Michigander! Leo at Koniks Klassics https://koniksklassiks.com/ In St Clair, MI may know of a 72 for sale. There are a few Michiganders here that have had 1st Gen Monte's for decades! -

-

-

Monte that sold at a local auction yesterday

Bob Hansen replied to TommySS454's topic in General 70-72 Monte Carlo Forum

-

Time to replace the bags

Bob Hansen replied to Bob Hansen's topic in General 70-72 Monte Carlo Forum

Exactly, I have 1 bad bag, but this way everything is new & I'll have spare components is something gets messed up. -

I've been using these Air Lift brand air bags forever. After 30 +/- years they no longer hold air for some reason. Initially got them for launch control & to reduce wheel hop. Having 5 to 7 lbs more in the right rear than left rear, it would keep the back end from sliding out to the right. They otherwise they provide a slightly stiffer feel and help to keep tires from rubbing under load. I was pleasantly surprised to find that they still make them for the Monte after all these years! here is the set I got. https://amzn.to/3gMuW4s Now to start clearing space to replace them when they get here! While it was well below zero out this morning , the Monte is ALWAYS kept well above freezing!

-

What did you do to your Monte Carlo today?

Bob Hansen replied to Canuck's topic in General 70-72 Monte Carlo Forum

Haven't had mine out in several years hoping to get it out this summer. I have most of what it needs except the time. Since it's been sitting (in a climate controlled environment) will be redoing the carb. It has needed a higher stall convertor, that has been purchased! Albeit for all the wrong reasons, the mud truck (see Locked-n-Loaded Mud Truck on Facebook) needed a stall convertor & the one in the Monte will be perfect for it, so a new one was bought for the Monte. The only thing left to get is a new driveshaft yoke for the TH400 as the current one has quite the groove worn into it which makes it leak. -

-

3rd gear usually goes out first then reverse will fail, and 1st & 2nd will work forever. Well that's been my TH350 experience anyway. 3rd & reverse use the same bands.

-

I twisted the guts out of a Summit Racing 2000 in less than 3000 miles. Put a B&M Holeshot 2000 in it and it behaved like a stock one, pulled it out and have a B&M Holeshot 2400 in it now. Oddly enough, the Summit 2000rpm one felt like it had a higher stall than the the B&M 2400 does

-

I did some research awhile back The B&M Holeshot convertors have a thrust bearing. The TCI convertors of the simular price range do not have a thrust bearing, yet their expensive ones do. So after breaking my Summit Racing brand convertor (TCI) I bouught a B&M holeshot 2000, should have went with the pricier 2400 though. as far as a convertor slipping in final drive, the only ones that don't are the "Lock Up" convertors. Typically, the higher the stall speed the more it slips in final drive.

-

One common item is that the driveshaft yoke can get wore down and gouged and will still leak with a new seal. Overfilling the trans will cause fluid to come out the vent on top of the case when the fluid heats up and expands. Remember a 1st Gen Monte does not leak!, It is just marking it's territory!

-

At www.gmpartsdirect.com they sell them for $8.73 ea that is also the same part # they show for the Chevelle, El Camino & Impala

-

You looking for springs or the hinges too? Leo, said used ones are better than any of the new ones out there. I learned he is right. The new ones I had bought from C.A.R.S. Inc, ended up bending and resulting in some nasty paint chips on top of my fenders. I have original 1st Gen Monte hinges on it now. If it is just the springs yer after, watch out that you don't get the lighter Chevelle springs.

-

Ok I'll chime in here too. The modulator controls all shifts, since it shifts from 1st to 2nd and not from 2nd to 3rd it is not a modulator issue. I think what he is saying is that when he places the shifter in D the trans engages (shifts) into first gear, then once under way it will shift up to second but will not make the leap to 3rd. One possibility is that someone has put a PowerGlide (2 spd) trans in the car. Another clue is "My dad fills it up with tranny fluid often" If the trans leaks when the fluid gets low, the pressure on the plates drops, they slip and wear out. Typically when a TH350 is on it's last legs, Drive (3rd) quits working and reverse starts to slip (3rd & Reverse use the same clutch pack) then reverse goes. I have seen TH350's continue to function on just 1st & 2nd long after drive & reverse failed.

-

A shorter drive shaft with a TH400 yoke on it. Possibly the shaft that your shifter linkage attaches to, the one that pivots in a bracket on the frame rail. If I remember correctly the TH350 one will work but the PRND2L in the dash will not line up quite right (visually). The trans crossmember is the same, just mounts in a different position. I can not think of anything different.

-

Thanks for the info Mike! Maybe I got lucky this time and it had a shift kit installed! It's a shame that the first trans couldn't hold up to an anemic 2.8L, even with the 3.73 gears, rebuilt once & failed again all within 135K

-

A note of caution a stock 700R4 is weak, subject to early failure with high temps. OD should never be used if towing. Around here the 700R4 costs nearly double to rebuild as compared to the TH350 & TH400. I understand that the 700R4 can be built to last.

-

After installing a used 700R4 tranny in my Blazer. I dropped the pan to change the filter I found a check ball in the pan Before I dropped the pan I had changed the throttle pressure cable from the outside, (undid the retainer bolt, pulled cable up, unhooked cable from pin, hooked new cable on, pushed it in and bolted it) Could this check ball have come from there???? Or is this just typical of my luck & the trans is probably junk

-

Unless it was built in Flint

-

Put the engine back in and try it I wish I had a good answer for ya, I'm no tranny expert but I would start with the vacumm line for the modulator. Did you rebuild the motor? Increase it's power? Maybe the tranny was on the edge and the new power plant is taking it's toll on the trans........ With any luck someone who actually knows what they are talking about will have an answer for ya.

-

This is a fairly simple task. First off with the car up on jack stands you should use a torque wrench to measure the turning resistance at the pinion ( force required to rotate axle assembly ). Mark the flange, flange nut and pinion with a paint marker to ensure they all go back on the same way. Remove the pinion nut then the pinion flange ( may require some light tapping ) replace the seal, (lithium based wheel bearing grease in seal lip) replace the flange ( do not hammer it on! ) The book procedure would be to snug the nut back up and check the rotating resistance with the torque wrench tighten it a little more check etc. etc. until you get to the same reading you had before you took it apart. This is where that paint mark comes in handy, you can tighten the nut back up until the paint marks line back up maybe just a hair past that. do not over tighten it!!! Think of the pinion bearings like front wheel bearings i.e. too tight it don't turn /too loose it rattles. This nut pinches the pinion bearings and a spacer (crush) sleeve between the pinion flange and the shoulder on the pinion gear. For reference only; it takes approximately 65 lbs of torque during initial assembly to set the pinion bearings to the proper preload when the axle is first put together. Or plan B, take it to a shop and pay about $50 & hope they do it right.