-

Posts

3,261 -

Joined

-

Last visited

-

Days Won

115

Content Type

Profiles

Articles

Forums

Gallery

Events

Everything posted by MC1of80

-

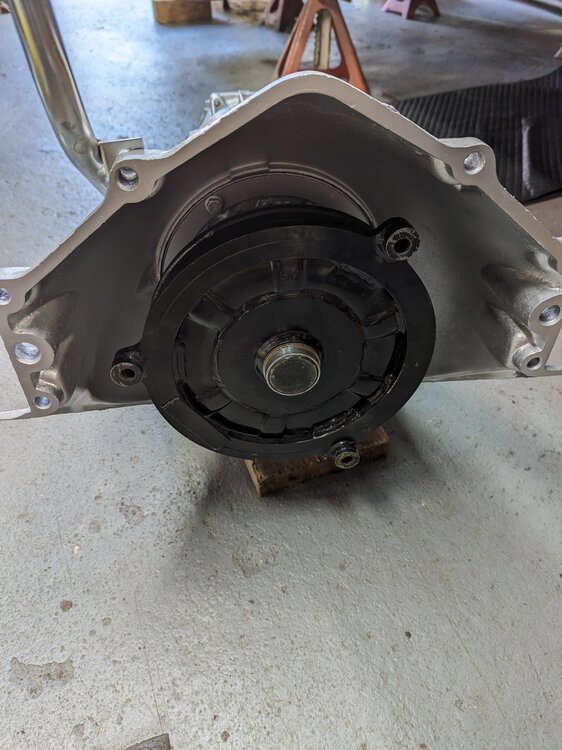

I agree for a stockish stall converter but a say 9" converter is small compared to stock and depending on the size of your hand, some can fit a fist between the converter and the transmission pump.

-

Nooooo! Install a qt of trans fluid into the converter if new. Then install it onto the transmission. Usually 3 clicks, clunks does it. This is while spinning the converter to line up the splines. You are mating the converter onto the shafts that stick out of the transmission and also engaging the pump in the transmission. Then mate it to the engine, the trans, that is. If done correctly, after the trans is installed you should be able to turn the converter by hand with no interference. You may actually have to pull/gently pry the converter towards the flywheel to be able to install the converter bolts.

-

What did you do to your Monte Carlo today?

MC1of80 replied to Canuck's topic in General 70-72 Monte Carlo Forum

I also noticed ALOT of hot spots on the flywheel and pressure plate. Good luck! -

New hardware is up to you. The factory stuff cleaned up is just fine though. Just make sure the converter is all the way into the transmission before mating the two. Everything else is personal preference.

-

Sorry Willie, the 454 didn't come out till 1970. Could be a 68 427 block. A 427 is basically a 454 (now) block and a 396 crank. Chevy stroked the crank to 4.0 to make the 454 with the 427 block in 70. Also, can you read the code off of the pad? It will tell you exactly what it's from and size. .060 overbore is max I would go without checking cylinder wall thickness. Since you have a bare block only I suggest the .060 overbore and a 4.250 stroke crank for a 496. Purchase a rotating assy. You will never regret it. 😁

-

Welcome Phil! She looks great! You have done a nice job indeed!

-

Nice job/save Dennis.

-

1972 MC 350/Auto - Roof, Sail Panel and Trunk Repair / Replace

MC1of80 replied to B-Man's topic in Auto Body Repair

Like cancer, that's just the surface that you see. I would personally, an have, change the 2 quarterpanels with either NOS or AMD. Also the panel between the rear window and trunk. As for the roof, the aftermarket now supplies a Monte Carlo specific roof skin. Kevin gets credit for removing and I stalling all metal. Lol he welds. I on the other hand do the bodywork and paint. We make a good pair. Lol -

Sorry, waited for someone else to answer, but alas, the 5 spoke factory rims used on the 71-72 Chevelle SS were FIRST seen on the 70 Camaro Z/28.

-

1972 MC 350/Auto - Suspension Upgrade

MC1of80 replied to B-Man's topic in Brakes and Suspension Tech

Just like Steve said. Put the jack under the shock/lower control arm mount and jack up till you can slip the coil in, repeat for other side. Ez pz. -

Dash light switch 72 Monte Carlo

MC1of80 replied to MrDavie's topic in General 70-72 Monte Carlo Forum

I'm sorry, maybe I misunderstood MrDavie's original post. I thought he wanted to know how to tighten his headlight switch not replace it. 🤔 Maybe I should read his original post again .... Slowly. -

Dash light switch 72 Monte Carlo

MC1of80 replied to MrDavie's topic in General 70-72 Monte Carlo Forum

Sorry, forgot to add, removal of the dashpad makes it easier. Screws are in the glove box, top and top of dash face. -

Dash light switch 72 Monte Carlo

MC1of80 replied to MrDavie's topic in General 70-72 Monte Carlo Forum

Remove the headlight knob bo pushing the "pin" on the switch itself. Then tighten the ferrel that attaches the switch to the dash. You may be able to tighten it without removing the knob but you will have to pull it out, turn on the lights. -

Congratulations! Quite a milestone. Happy 200k more!

-

Sooo sorry for your loss Willie. Our thoughts and prayers to you and your family. Should you need ANYTHING.....🙏

-

1971 center console neutral safety switch.

MC1of80 replied to Whons's topic in Cars and Parts For Sale/Wanted

-

Huh? I came up with one for 71 on our site. T0904CPD= Tonawanda plant Sept 4th CPD- 454 w/th400

-

Price what you have now in NYC or one of the 5 boroughs. You will be MORE than happy for what you are paying. Just saying.

-

What did you do to your Monte Carlo today?

MC1of80 replied to Canuck's topic in General 70-72 Monte Carlo Forum

Definitely not Aaron but funnnnnnnny! -

They can take way more torque than that. As a "wee one" 17 yr old working at a transmission shop we used to install all pressure plate and flywheel bolts with 1/2" air impact guns. Never checked torque and thankfully no failures. Didn't know or care about "torque" specs. Back then. Know better now. I guess... 😂🤣😂

-

ARP bolts are always better. The price, not so much. If you plan on "playing" a little, then you can't go wrong with ARP. But also remember, the factory bolts are plenty strong also.

-

What did you do to your Monte Carlo today?

MC1of80 replied to Canuck's topic in General 70-72 Monte Carlo Forum

Looks rebuilt already Aaron. Lolol -

If the engine matches the TRIM tag build date, the car you are looking at most likely has been tagged. NO GM vehicle has a trim tag from one plant and a vin from a totally different plant. Somewhere along the line someone most likely did something fishy.

-

Good job Dennis. Kevin's truck is waiting for you. I believe his has at least 4 broken bolts.

-

What did you do to your Monte Carlo today?

MC1of80 replied to Canuck's topic in General 70-72 Monte Carlo Forum

Looks like you already got the bushing out. Next time, or better yet, on someone else's car try filling the hole and crank wit a piece of bread or grease, use a 1/2 drive extension and hammer it in. 9 outa 10 times this works flawlessly.